We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

9RT engine

9RT engine 9RT with Cummins X15 15.0L engine

9RT with Cummins X15 15.0L engineJohn Deere and Cummins have partnered to provide customers with a reliable, productive and efficient engine solution in the X15. Extensive work has been done between John Deere and Cummins on software development and other engine/tractor application interface points to provide producers with the performance and efficiency they have come to expect from John Deere.

The X15 has followed the same building block approach to meet emissions requirements as similar John Deere engines. This allows John Deere to provide common technologies to producers throughout different horsepower and engine displacement offerings ensuring a consistent experience for producers. Just like the other two engine offerings in the 9 Family of tractors, the X15 features exhaust gas recirculation (EGR) and an exhaust aftertreatment combination of a diesel particulate filter (DPF) and selective catalytic reduction (SCR) to meet the near-zero NOx and particulate matter (PM) emissions standards.

X15 technology

XPI fuel system – the XPI common-rail fuel system delivers a precise quantity of fuel at ultra-high pressures. This, together with electronic engine controls, enables multiple injection events per cycle. Flexibility in injection timing increases fuel economy and performance while decreasing exhaust emissions.

VGT turbocharger – the X15 utilizes a single Cummins VGT™ turbocharger which features electric actuation for infinite adjustment.

Cooled EGR –system has been rebalanced for use with SCR, reducing flow volume and minimizing diesel exhaust fluid (DEF) consumption levels.

Fully integrated electronic controls – a single electronic control module (ECM) controls everything from air intake to exhaust aftertreatment.

Cummins particulate filter and SCR – Cummins particulate filter operates as a nearly passive device, with minimal regeneration required.

Cummins and VGT are a trademarks of Cummins Inc.

CommandView III cab

CommandView III cabThe standard CommandView III cab offers unsurpassed visibility, operator comfort, control placement, and ride and sound quality.

Features:

ComfortCommand seat

ComfortCommand seatComfortCommand seat improves ride quality and helps to reduce operator fatigue

Features include:

CommandARM controls

CommandARM controlsJohn Deere 9 Family Tractors feature the CommandARM with integrated Generation 4 CommandCenter display. The control layout of the CommandARM utilizes a clean and efficient design which groups controls by function and builds upon John Deere’s history of intuitive and ergonomic control placement and operation. The design of the CommandARM allows for a 40-degree right seat swivel and adjustable positioning matching the operator’s preference.

Controls located on the CommandARM include:

Hydraulic controls utilize fingertip paddle pots for raise/lower and extend/retract functions.

Fingertip paddle pots

Fingertip paddle potsThrottle

The throttle design incorporates buttons which control FieldCruise speed, and transmission eco settings.

Throttle

ThrottleTractor function controls

Located just to the right of the throttle is the Auto-Trac activation button and four sequence controls for iTEC functions. Behind the iTEC sequence controls there are buttons which control the activation and deactivation of differential lock. Differential lock can also be activated by the foot switch on the cab floor.

AutoTrac resume and iTEC strip

AutoTrac resume and iTEC stripControls for radio, lights, rotary beacon (if equipped), hazard flashers, and HVAC system are located to the center-right on the CommandARM, along with power take-off (PTO) for rear PTO.

Generation 4 CommandCenter

Generation 4 CommandCenterThe Generation 4 CommandCenters features fast adjustment of tractor functions and controls and are integrated into the CommandARM to create a seamless control center.

The following functions can be adjusted and accessed using the CommandCenter display:

The Generation 4 CommandCenter systems have the capability of Remote Display Access (RDA). RDA allows improved communication between an offsite farm manager or dealer and the equipment operator. The user can view exactly what the operator sees on the GreenStar™ 3 2630 Display and Generation 4 CommandCenter from almost any internet-connected device. RDA is available on the 4600 and 4100 CommandCenter and allows for an increase in productivity with quicker problem resolution. By using RDA, the cost of operation will decrease due to reduced labor and travel costs, and maximum efficiency will increase profit.

Radio, HVAC, hazard flashers, and PTO controls

Radio, HVAC, hazard flashers, and PTO controlsSeat swivel

The design of the CommandARM allows for up to 40 degrees of right-hand seat swivel.

Seat swivel

Seat swivel 40-degree seat swivel shown

40-degree seat swivel shownThe e18 transmission delivers smooth shifting and intuitive controls in a reliable 18-speed PowerShift transmission. The e18 transmission with enhanced Efficiency Manager is standard equipment on all 9 Family Tractors.

The e18 has evolved from more than 50 years of John Deere PowerShift technology. With more automatic features, the e18 is easy to operate for all levels of operators and operations. It features three modes of operation, full AUTO, custom, and manual modes. Full AUTO and custom modes manage the engine and transmission to match the desired ground speed to the field conditions. These two modes are ideal for most conditions and take the guess work out of operation. Manual mode is perfect for operators looking to operate the e18 like a traditional PowerShift by bump shifting and managing the engine throttle to their liking.

As the next generation of PowerShift technology, the e18 delivers the strength to handle sudden, high-torque power loads while maintaining responsive, quick, and smooth shifts.

Shift lever and hand throttle

Shift lever and hand throttle 254-mm (10-in.) Generation 4 CommandCenter

254-mm (10-in.) Generation 4 CommandCenterThe CommandCenter is the central information system for tractors and allows the operator to program various settings tailored to a specific operation.

To access the tractor’s transmission settings, press the transmission shortcut button on the CommandCenter shortcut bar.

CommandCenter transmission shortcut button

CommandCenter transmission shortcut buttonOperating modes

The e18 application settings employ three modes to take full advantage of the engine-transmission communication: Full AUTO mode, custom mode, and manual mode.

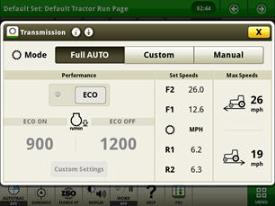

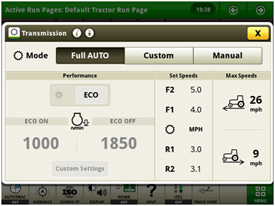

Full AUTO main page

Full AUTO main pageFull AUTO mode manages the tractor’s engine and transmission inputs to reach and maintain the desired ground speed set by the operator. This means the tractor will manage shifts and engine rpm to operate at the most efficient level possible. Operators have the ability to set the maximum forward and reverse speeds for their particular applications. In full AUTO mode the operator can adjust the desired ground speed in two ways, by conducting a traditional bump shift or by rotating the dial on the thumb wheel.

When shifting in full AUTO mode, the transmission shifts set speeds and does not always shift gears, meaning the transmission may not necessarily shift gears if it can reach the desired ground speed with a slightly higher or lower engine rpm. Efficiency Manager is automatically engaged while operating in full AUTO mode. As a result, shifting will not take the tractor out of Efficiency Manager in full AUTO mode.

e18 custom transmission page

e18 custom transmission pageCustom mode operates similar to full AUTO mode but allows operators to adjust operating parameters to meet a specific operation. It also has the ability to activate eco mode for a higher level of operation.

Eco button

Eco button Display screen

Display screenEco allows two minimum engine speeds to be set. Operators can turn eco on and off by either pushing the eco button on the side of the throttle or by selecting eco in the transmission settings page of the CommandCenter controls. For example, operators may choose to turn eco on during transport to utilize a lower minimum engine speed and then turn eco off while operating in the field where a higher minimum engine speed is desired.

Set speed buttons and set speed adjuster

Set speed buttons and set speed adjusterEfficiency Manager is automatically enabled in auto and custom modes. Efficiency Manager can be turned on in manual mode by selecting the set speed one or set speed two button on the CommandARM™ console. The set speed adjuster on the top of the single-lever gear selector allows the operator to dial in the desired ground speed to establish set speed one or two. Once engaged, Efficiency Manager will manage the engine rpm and gear selection to maintain the desired working speed. To reach the desired set speed, the throttle must be set to full engine rpm.

Custom settings page

Custom settings pageIn the advanced settings page, operators can customize the auto shift engine speed droop as a percentage of the full engine speed. In addition, the load anticipation feature can be enabled for the hitch engagement, hydraulic engagement, or both.

Manual mode

Manual mode operates very similarly to a traditional PowerShift transmission with Efficiency Manager.

In manual mode the operator manages the engine and transmission inputs by controlling the shift lever and hand throttle.

Manual mode page

Manual mode page e18 operation

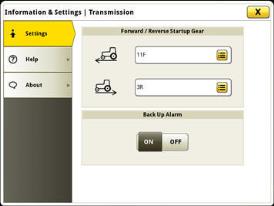

e18 operationSetting start-up gears

The 9 Family Tractors default to 7F and 2R at start up. However, these default start-up gears can be adjusted from 1-13F and 1-3R through the CommandCenter. Refer to the operator’s manual for additional information.

Start-up gears in advanced settings

Start-up gears in advanced settings9R Series Tractor - e18-speed chart for PowerShift transmission with Efficiency Manager

9R table

Group 47 tires | Group 48 tires | |||

Tire size | (480R46, 20.8R42, 520R42, 620R42, 710R38) | (480R50, 520R46, 620R46, 710R42, 800R38) | ||

Engine (rpm) | 2100 | 2100 | ||

18-speed gear | km/h | mph | km/h | mph |

Forward gears | ||||

F1 | 4.0 | 2.5 | 4.2 | 2.6 |

F2 | 4.8 | 3.0 | 5.0 | 3.1 |

F3 | 5.3 | 3.3 | 5.6 | 3.5 |

F4 | 5.9 | 3.7 | 6.2 | 3.9 |

F5 | 6.5 | 4.0 | 6.8 | 4.3 |

F6 | 7.3 | 4.5 | 7.6 | 4.8 |

F7 | 8.0 | 5.0 | 8.5 | 5.3 |

F8 | 9.0 | 5.6 | 9.5 | 5.9 |

F9 | 9.9 | 6.1 | 10.4 | 6.5 |

F10 | 11.0 | 6.9 | 11.6 | 7.2 |

F11 | 12.2 | 7.6 | 12.9 | 8.0 |

F12 | 13.5 | 8.4 | 14.2 | 8.8 |

F13 | 15.0 | 9.3 | 15.8 | 9.8 |

F14 | 16.6 | 10.3 | 17.5 | 10.9 |

F15 | 20.5 | 12.8 | 21.6 | 13.4 |

F16 | 25.3 | 15.7 | 26.6 | 16.5 |

F17 | 31.2 | 19.4 | 32.9 | 20.4 |

F18 | 38.5 | 23.9 | 40.5 | 25.2 |

Reverse gears | ||||

R1 | 3.9 | 2.4 | 4.1 | 2.5 |

R2 | 5.3 | 3.3 | 5.6 | 3.5 |

R3 | 5.9 | 3.7 | 6.2 | 3.9 |

R4 | 8.0 | 5.0 | 8.5 | 5.3 |

R5 | 9.0 | 5.6 | 9.5 | 5.9 |

R6 | 12.2 | 7.6 | 12.9 | 8.0 |

Group 47 tire based on 710/70R38

Group 48 tire based on 800/80R38

9RT and 9RX Series Tractor - e18-speed chart for PowerShift transmission with Efficiency Manager

9RT and 9RX table

| 9RT | 9RX | ||

Engine (rpm) | 2100 | 2100 | ||

18-speed gear | km/h | mph | km/h | mph |

Forward gears |

|

|

|

|

F1 | 4.0 | 2.5 | 4.0 | 2.5 |

F2 | 5.0 | 3.1 | 4.9 | 3.0 |

F3 | 5.5 | 3.4 | 5.5 | 3.4 |

F4 | 6.1 | 3.8 | 6.1 | 3.8 |

F5 | 6.8 | 4.2 | 6.7 | 4.2 |

F6 | 7.6 | 4.7 | 7.5 | 4.7 |

F7 | 8.4 | 5.2 | 8.3 | 5.2 |

F8 | 9.3 | 5.8 | 9.2 | 5.7 |

F9 | 10.3 | 6.4 | 10.2 | 6.3 |

F10 | 11.4 | 7.1 | 11.4 | 7.1 |

F11 | 12.6 | 7.8 | 12.6 | 7.8 |

F12 | 14.1 | 8.7 | 14.0 | 8.7 |

F13 | 15.6 | 9.7 | 15.5 | 9.6 |

F14 | 17.3 | 10.7 | 17.2 | 10.3 |

F15 | 21.4 | 13.3 | 21.3 | 13.2 |

F16 | 26.3 | 16.3 | 26.2 | 16.3 |

F17 | 32.3 | 20.1 | 32.2 | 20.0 |

F18 | 39.8 | 24.7 | 39.6 | 24.6 |

Reverse gears |

|

|

|

|

R1 | 4.0 | 2.5 | 4.0 | 2.5 |

R2 | 5.5 | 3.4 | 5.5 | 3.4 |

R3 | 6.1 | 3.3 | 6.1 | 3.8 |

R4 | 7.3 | 3.8 | 8.3 | 5.2 |

R5 | 9.3 | 5.8 | 9.2 | 5.7 |

R6 | 12.6 | 7.8 | 12.6 | 10.3 |

JDLink Dashboard

JDLink DashboardJDLink is the John Deere telematics system designed for operators and managers who desire to take their operations to the next level of productivity and efficiency without leaving the office. Whether it is receiving an e-mail or text message, users can manage the operation in real-time without being in the cab. Using the power of JDLink can optimize productivity, increase uptime, and boost profits with JDLink information all accessible from a laptop, desktop, or mobile device.

JDLink Ultimate provides enhanced machine performance and utilization information that can only be achieved through direct communication with on-board machine controllers. Utilizing John Deere-exclusive telematics technology, users can remotely link to Ultimate-compatible machines to achieve a new level of optimization.

NOTE: Mobile device compatibility and functionality varies.

Monitor assets, performance, and more with JDLink:

For more information on JDLink activations and subscriptions, visit www.StellarSupport.com.

NOTE: JDLink is not available in all geographic regions.

Service ADVISOR

Service ADVISORService ADVISOR diagnostics greatly assist in reducing service costs and downtime. It allows the John Deere service technician to readily extract vital information about tractor malfunctions through the Service ADVISOR data port. Diagnostic codes and controller area network (CAN) bus statistics stored by the tractor and visible in the CommandCenter™ display are used by service technicians to isolate, identify, and resolve problems.

Diagnostics and CAN bus statistics are not normally used by the operator. Access and use of trouble codes should only be done by a qualified, factory-trained John Deere service technician.

Service ADVISOR Remote takes the machine connectivity of JDLink and takes it one step further. With Service ADVISOR Remote, machines can be diagnosed remotely, saving the cost of a field service call. For example, diagnostic trouble codes can be reset and software updates can be uploaded remotely.

Apple, iPhone, and iPad are trademarks of Apple Inc. Android is a trademark of Google LLC.

High flow hydraulics

High flow hydraulics

The 115-gpm (435 L/min) hydraulic system (order code 2813) is designed to reduce scraper hydraulic cycle times, thus increasing the efficiency of the tractor/scraper combination.

Two hydraulic pumps are combined for a total of 115-gpm (435 L/min). Flow through one 19.1-mm (3/4-in.) SCV is 45 gpm (140 L/min). The selective control valves (SCVs) are designed for commercial applications. This system is not recommended for agricultural implements with continuous flow requirements. When maximum hydraulic pump capacity is reached, multiple functions will continue to operate at the same proportional flow rate. This will prevent the rear scraper from slowing down, in relation to the front scraper, when operating the front and rear scrapers at the same time.

When ordering this scraper high-flow option, the tractor will come standard with four SCVs. The two system pumps provide their combined oil flow of 115 gpm (435 L/min) to all four SCVs through a common valve manifold. All of the SCV oil returns to one common reservoir.

19.1-mm (3/4-in.) couplers reduce restriction for increased flow to the scraper. A secondary lowering function accumulator is included with the hydraulic valves so the scraper can be lowered if hydraulic power is lost.

NOTE: This system is not recommended with agricultural implements with continuous flow demand (scraper applications only).

IMPORTANT: Do not use this system with scrapers/implements with 12.7-mm (1/2-in.) couplers/hoses/hydraulic systems. Damage could occur to implement hoses/couplers/components due to high-flow capability of the tractor system.

NOTE: Power Beyond connections are not recommended for use with scraper systems or high hydraulic oil take out demand (example: large or multiple single acting cylinders, raising multiple scraper pans). Power Beyond connections are recommended for agricultural equipment with continuous flow demands (example: variable rate drives, CCS fans).

PST with Efficiency Manager on 9R Sraper Special Tractor

PST with Efficiency Manager on 9R Sraper Special Tractor

Exclusively designed for the 9R Series Tractors, the 18-speed full PowerShift Transmission with Efficiency Manager is standard on the 9460R - 9560R and 9RT Scraper Tractors. The 18-speed transmission features include:

The 9RT offers increased speed up to 40 K/h (25 mph). Gear ratios on the track tractors have increased approximately 16.5% across the board providing increased speed at respective levels on the 9030T.

Full powershifts for on-the-go shifting.

| Group 47 | Group 48 | ||

| (480R46, 20.8R42, 520R42, 620R42, | (480R50, 520R46, 620R46, 710R42, | ||

Tire Size | 710R38) | 800R38) | ||

Engine (rpm) | 2100 | 2100 | ||

24-Speed Gear | Mph | Km/h | Mph | Km/h |

Range/Speed |

|

|

|

|

F1 | 2.54 | 4.08 | 2.69 | 4.33 |

F2 | 3.12 | 5.02 | 3.31 | 5.33 |

F3 | 3.45 | 5.55 | 3.66 | 5.89 |

F4 | 3.89 | 6.21 | 4.09 | 6.59 |

F5 | 4.25 | 6.84 | 4.50 | 7.25 |

F6 | 4.75 | 7.64 | 5.04 | 8.11 |

F7 | 5.25 | 8.45 | 5.57 | 8.97 |

F8 | 5.83 | 9.39 | 6.20 | 9.97 |

F9 | 6.46 | 10.40 | 6.86 | 11.04 |

F10 | 7.16 | 11.56 | 7.62 | 12.26 |

F11 | 7.93 | 12.77 | 8.42 | 13.55 |

F12 | 8.83 | 14.21 | 9.37 | 15.08 |

F13 | 9.77 | 15.72 | 10.36 | 16.68 |

F14 | 10.87 | 17.49 | 11.53 | 18.56 |

F15 | 13.43 | 21.62 | 14.25 | 22.94 |

F16 | 16.53 | 26.60 | 17.54 | 28.23 |

F17 | 20.29 | 32.66 | 21.53 | 34.65 |

F18 | 24.99 | 40.21 | 26.51 | 42.67 |

|

|

|

|

|

R1 | 2.54 | 4.08 | 2.69 | 4.33 |

R2 | 3.45 | 5.55 | 3.66 | 5.89 |

R3 | 3.89 | 6.21 | 4.09 | 6.59 |

R4 | 5.25 | 8.45 | 5.57 | 8.97 |

R5 | 5.83 | 9.39 | 6.20 | 9.97 |

R6 | 7.93 | 12.77 | 8.42 | 13.55 |

Group 47 Tire based on 710/70R38

Group 48 Tire based on 800/85R38

Engine (rpm) | 2100 | |

Range/Speed | Mph | Km/h |

F1 | 2.53 | 4.07 |

F2 | 3.11 | 5.01 |

F3 | 3.44 | 5.54 |

F4 | 3.85 | 6.19 |

F5 | 4.23 | 6.81 |

F6 | 4.73 | 7.62 |

F7 | 5.23 | 8.42 |

F8 | 5.82 | 9.36 |

F9 | 6.44 | 10.37 |

F10 | 7.16 | 11.52 |

F11 | 7.91 | 12.73 |

F12 | 8.80 | 14.16 |

F13 | 9.74 | 15.67 |

F14 | 10.83 | 17.43 |

F15 | 13.39 | 21.55 |

F16 | 16.47 | 26.51 |

F17 | 20.23 | 32.55 |

F18 | 24.90 | 40.08 |

|

|

|

R1 | 2.53 | 4.07 |

R2 | 3.44 | 5.54 |

R3 | 3.85 | 6.19 |

R4 | 5.23 | 8.42 |

R5 | 5.82 | 9.36 |

R6 | 7.91 | 12.73 |

9R, 9RT, and 9RX service access

9R, 9RT, and 9RX service accessRegular service and maintenance are essential to the performance, productivity, and longevity of all farm machinery.

Maximum uptime is an important element of productivity.

All items in the daily service schedule can be performed without the use of tools:

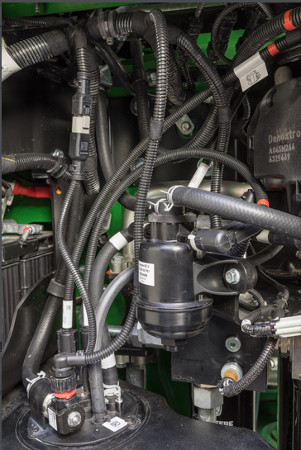

Engine oil service point

Engine oil service point

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.

Fuel tank on the 9R

Fuel tank on the 9R Refueling

RefuelingThe 9R Series Tractors fuel tank is located over the rear axle. The fuel tank features a dual fill design. This design allows the machine to be filled from either side of the fuel tank. A fuel nozzle holder is located when the operator positions themselves on the gudgeon platform to fill the fuel tank.

The diesel exhaust fluid (DEF) tank is located on the left-hand side of the tractor indicated by a blue cap. It is fillable from ground level and has a protective shield to keep debris out of the fill neck.

Model | Diesel | DEF |

9370R | 1211 L (320 gal.) | 120 L (31.7 gal.) |

9420R | 1514 L (400 gal.)* | 120 L (31.7 gal.) |

9470R | 1514 L (400 gal.)* | 120 L (31.7 gal.) |

9520R | 1514 L (400 gal.) | 120 L (31.7 gal.) |

9570R | 1514 L (400 gal.) | 120 L (31.7 gal.) |

9620R | 1514 L (400 gal.) | 120 L (31.7 gal.) |

*When equipped with double-reduction axle. 1211-L (320-gal.) when equipped with single-reduction axle.

9R, 9RT, and 9RX Series Tractors feature an easy-to-use DEF fill system. The 9R and 9RX feature a ground-level fill location, and DEF fill on 9RT is conveniently located on the step platform.

| Machine | DEF tank capacity |

| 9R | 120 L (31.7 gal.) |

| 9RT | 93.9 L (24.8 gal.) |

| 9RX | 120 L (31.7 gal.) |

DEF tank on 9R/9RX

DEF tank on 9R/9RX9R, 9RT, and 9RX Series Tractors feature an in-line DEF filter to help protect the DEF pump from any contamination in the DEF tank. This in-line DEF filter is easily serviced with a drain plug to drain any remaining DEF from the filter housing and a replaceable cartridge-style filter.

Engine access on 9RX

Engine access on 9RXThe tilt hood and side panel design provides additional engine compartment protection. The 9R, 9RT, and 9RX hoods feature the same design for access to engine components.

Pull out the hood release (located on the front, left side) and tilt hood back to open. Engine side panels are quickly and easily removed for access to periodic maintenance items.

Fuel tank on the left side of 9RT

Fuel tank on the left side of 9RTThe 9RT fuel tank is located behind the cab; the fuel fill is located conveniently on the left-hand main platform.

The 9RT Series Tractors all feature a DEF tank capacity of 93.9 L (24.8 gal.). The fill location is near the diesel fill location.

Model | Diesel | DEF |

9470RT | 1325 L (350 gal.) | 93.9 L (24.8 gal.) |

9520RT | 1325 L (350 gal.) | 93.9 L (24.8 gal.) |

9570RT | 1325 L (350 gal.) | 93.9 L (24.8 gal.) |

Model | Diesel | DEF |

9470RX | 1514 L (400 gal.) | 120 L (31.7 gal.) |

9520RX | 1514 L (400 gal.) | 120 L (31.7 gal.) |

9570RX | 1514 L (400 gal.) | 120 L (31.7 gal.) |

9620RX | 1514 L (400 gal.) | 120 L (31.7 gal.) |

NOTE:

For more information about the use of bio-diesel in John Deere engines, refer to www.JohnDeere.com/biodiesel.

In-line DEF filter

In-line DEF filterSevere-duty water separator, if equipped

The severe-duty water separator can extend service intervals and helps to protect the tractor’s fuel system from damage associated with lower-quality fuel.

Simply open the drain valve on the bottom of the separator and drain accumulated water.

NOTE: Cummins® QSX 15 L (915.4-cu in.) engines cannot be equipped with a severe-duty water separator; however, the fuel filter has separating capabilities like the primary filter on John Deere Power System engines.

Removing side engine panel

Removing side engine panel Primary engine air filter inspection

Primary engine air filter inspectionOn the 9R and 9RX, the primary engine air filter is accessible from the left-hand platform for replacement annually or as operating conditions require. The filter is aspirated and extends filter life in dusty conditions by aspirating more than 95 percent of incoming dust. Aspirator suction is created by utilizing the air flow from the cooling fan.

On the 9RT, the primary engine air filter is located at ground level on right side of tractor.

Battery location on 9R and 9RX

Battery location on 9R and 9RX Battery location on 9RT

Battery location on 9RTThe 9R and 9RX battery location is behind the left-hand step assembly. There are three bolts that secure the swinging step assembly that need to be removed to completely access the batteries. The 9RT top step of the platform conceals the tractor’s three 12-V batteries with 2775 CCA (925-CCA each). Tractors with the Cummins X15 engine will have four 12-V batteries in the same location as tractors equipped with John Deere Power System engines.

Although the batteries are maintenance free, conditions such as long periods of operation at high ambient temperatures and excessive engine cranking may require adding water.

Battery boost terminal

Battery boost terminalOn the 9R and 9RX, a battery boost terminal is located on the left-hand side of the engine for convenient and proper boost assisted starting.

Windshield washer bottle on 9R and 9RX

Windshield washer bottle on 9R and 9RXThe windshield washer bottle is optional on 9R and 9RX Tractors and is located on the left side of the tractor near the DEF fill point. On 9RT Tractors, it is located on the right-side frame.

Maintenance-free U-joint bearings require no servicing to reduce maintenance time.

Sight gauge on 9R and 9RX

Sight gauge on 9R and 9RX Sight gauge on 9RT

Sight gauge on 9RTA sight glass for the transmission, hydraulic, and axle oil level is located at the back right side of the gudgeon, indicating proper oil levels, and an oil fill neck is located on the back right side of the gudgeon for the 9R and 9RX Series Tractor. The oil fill is located on the top of the common reservoir on the left side of the 9RT Series Tractor and a fill tube is located between the steps and engine of the tractor.

NOTE: The tractor should be off and parked on level ground with the hitch in the lowered position when checking the oil level.

NOTE: Oil level above the top mark on the sight glass can result in power loss and heat generation during transport applications.

Engine oil check/fill location

Engine oil check/fill locationTractors with the 9.0L (549.2-cu in.) and 13.5L (823.2-cu in.) John Deere Power Systems engines feature a 500-hour change interval when using approved John Deere Plus-50™ II oil and a John Deere oil filter.

Tractors equipped with the Cummins QSX 15-L (915.4-cu in.) engine have a 400-hour engine oil and oil filter change interval.

See the tractor's operator's manual for oil change intervals and further details.

Fuse and relay panel

Fuse and relay panelThe electrical fuse and relay panel is located behind the operator’s seat and just below the cab's rear window. Simply lift up on the operator manual cover for access.

The diode module contains many of the diodes contained in the system:

Electrical system (smart load center)

The electrical system provides a full controller area network (CAN) bus based system on the tractor for improved tractor implement integration and flexibility. Incorporated with the system is a smart load center, which provides fewer fuses, fewer connectors, and simplified wiring for increased reliability.

The solid-state load center’s primary function is to control the majority of high-current loads, such as fender floodlights and the horn. This electronic circuitry will monitor loads and voltages to provide fast reaction time and the ability to alert the operator if a circuit overloads or if voltage is out of specification – for example, open circuit (undercurrent) or short circuit (overcurrent).

Cab fresh air filter inspection

Cab fresh air filter inspection Cab recirculation filter

Cab recirculation filterThe cab fresh air filter is conveniently located beneath the left side of the cab for all 9 Family products:

Cab air recirculation filter

Cab air recirculation filter is located in the roof liner above the operator. 70 percent of the total air volume is recirculated with a blanket effect for enhanced operator comfort.

Cab air filters are not designed to filter out harmful chemicals. Follow the instructions in the implement operator’s manual and those given by the chemical manufacturer when using agricultural chemicals.

Toolbox for 9R, 9RT and 9RX

Toolbox for 9R, 9RT and 9RXA convenient toolbox is located on the left-hand side of the front frame for tool storage and comes standard on all 9R, 9RT, and 9RX Series Tractors.

9R and 9RX Series Tractors have an additional storage box conveniently located on top the left-hand platform.

The 9RT has an additional toolbox conveniently located next to the left side of the batteries for additional storage.

Cummins is a trademark of Cummins, Inc.

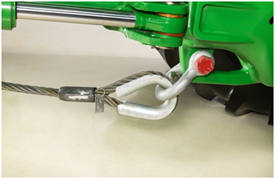

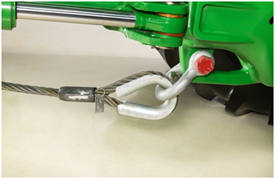

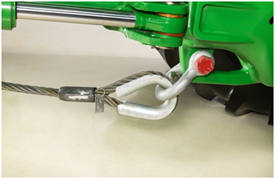

Tow cable front hook

Tow cable front hook Rear tow cable connection point

Rear tow cable connection pointThe front tow cable is recommended for pulling all 9 Family Tractors in time of needed assistance. Tow cables are available as a factory-installed option on all ag tractors and are base equipment on all Scraper Special Tractors. The tow cable attaches to the area in front of the drawbar and is also available as a field-installed option.

Compare the specifications of up to 4 models

| Key Specs | 9620r-scraper-special-tractor Current Model |

|---|---|

| Engine description | Cummins QSX15 (B20 diesel compatible) |

| Engine displacement | 14.9 L 912 cu in. |

| Rated engine power | 456 kW 620 hp |

| Rated PTO power (hp SAE) | |

| Transmission type | Standard: John Deere e18™ 18-speed PowerShift with Efficiency Manager™: 40 km/h 25 mph |

| Hydraulic pump rated output | Standard: 220 L/min 58 gpm Optional: 435 L/min 115 gpm |

| Rear hitch category (SAE designation) | |

| Base machine weight | 18,970 kg 41,820 lb |

| Maximum PTO power | |

| Maximum engine power | |

| Engine specifications | |

| Description | Cummins QSX15 (B20 diesel compatible) |

| Engine type | Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with 4 valves-in-head |

| Engine family | |

| Rated speed | 2,100 rpm |

| Aspiration | Single Variable geometry turbocharger with air-to-air aftercooling and cooled exhaust gas recirculation |

| Cylinders liners | |

| Emission level | Final Tier 4 |

| After treatment type | DOC/DPF/SCR |

| Displacement | 14.9 L 912 cu in. |

| Engine performance | |

| Rated power | 456 kW 620 hp |

| Rated PTO power (hp SAE) | |

| Power boost | 8 percent |

| Engine peak torque | At 1600 rpm: 2800 Nm 3800 lb-ft |

| PTO torque rise | 36 percent |

| Intelligent Power Management (available in transport and/or mobile PTO applications) | |

| Maximum PTO power | |

| Maximum engine power | |

| Transmission | |

| Type | Standard: John Deere e18™ 18-speed PowerShift with Efficiency Manager™: 40 km/h 25 mph |

| Reverser | |

| Clutch; wet/dry | |

| Creeper | |

| Hydraulic system | |

| Type | |

| Pump rated output | Standard: 220 L/min 58 gpm Optional: 435 L/min 115 gpm |

| Available flow at a single rear SCV | 0.5 in. couplers: 132 L/min 35 gpm 0.75 in. couplers: 159 L/min 42 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | Standard: ISO Couplers: 4-6 Optional: ISO Couplers: 7-8 (field installed) |

| Number of mid selective control valves (SCVs) | |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | |

| SCV control | Electronic |

| Rear hitch | |

| Hitch draft control load sense type | |

| Remote control valves available | |

| Hitch category (SAE designation) | |

| Maximum lift capacity behind lift points | |

| Sensing type | |

| Rear axle differential lock | |

| Lift capacity at standard frame | |

| Drawbar | |

| Drawbar category | Standard: Drawbar Support for Short Scraper Drawbars Optional: Drawbar Support for Long Scraper Drawbars |

| Maximum vertical load | |

| Rear power take-off (PTO) | |

| Type | |

| Engine rpm (at rated PTO speeds) | |

| PTO actuation | |

| Ground speed PTO option availability | |

| Multispeed PTO option availability | |

| Front hitch | |

| Category | |

| Electric power | |

| Standard lift capacity | |

| Front power take-off (PTO) | |

| PTO speed | |

| Rear axle | |

| Type | Standard: Diameter: 120 x 3,048 mm 4.72 x 120 in. |

| Final drive type | Inboard planetary with double-reduction axle |

| Differential controls | |

| Axle type | |

| Brakes, type and control | |

| Rear differential lock | Full-locking electrohydraulic |

| Load rating | |

| Front axle | |

| Type | Standard: Diameter: 120 x 3,048 mm 4.72 x 120 in. |

| Front axle differential lock | Full-locking electrohydraulic |

| Load rating | |

| Tires | |

| Front | |

| Rear | |

| Wheel tread range | |

| Turning radius with brakes | |

| Turning radius without brakes | Group 47 tires: 6,035 mm 19.8 ft |

| Steering | |

| Electrical system | |

| Alternator size | Standard: 200 amp Optional: 240 amp |

| Battery options | 12 V |

| Total cold cranking amps | 925 CCA |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| Type of bulb in headlight (Halogen, Zenon, LED) | |

| Working lights | |

| dB(A) rating for backup alarm | |

| Operator station | |

| Rollover protective structure, OOS | |

| Seat | Standard: ComfortCommand™ Optional: ActiveSeat™ |

| Cab suspension | |

| Instructional seat | Standard |

| Display | Standard: 4100 Generation 4 CommandCenter™ with 7 in. display Optional: 4600 Generation 4 CommandCenter™ with 10 in. display |

| Radio | Standard: AM/FM stereo with weatherband, remote controls, auxiliary input jack, four speakers and external antenna |

| Inner cab volume | 3.597 m3 127 cu ft |

| dB(A) rating | |

| Cab glass area | 6.52 m2 70.18 sq ft |

| Front visibility | |

| Safety glass rating | |

| Dimensions | |

| Wheelbase | 3,912 mm 154 in. |

| Overall length | With front weights, excluding hitch and coupler: 7,697 mm 303 in. |

| Drawbar clearance | Group 48 tires: 447 mm 17.6 in. |

| Front axle center | |

| Approximate shipping weight, Open;Cab | 18,970 kg 41,820 lb |

| Overall height | |

| Weight | |

| Base machine weight | 18,970 kg 41,820 lb |

| Maximum ballast level | 24,494 kg 54,000 lb |

| Maximum permissible weight | |

| Capacities | |

| Crankcase oil volume | 43.5 L 11.5 U.S. gal. |

| Fuel tank | 1,514 L 400 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 83 L 22 U.S. gal. |

| Cooling system | 62 L 16.3 U.S. gal. |

| Transmission-hydraulic system | With 3-point hitch and PTO: 223 L 59 U.S. gal. |

| Serviceability | |

| Interval for engine oil change | 400 hours |

| Interval for hydraulic/transmission oil change | 1,500 hours |

| Interval for engine coolant change | 6,000 hours |

| Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Precision AG | |

| Guidance | AutoTrac Ready |

| Telematic | Available with JDLink™ hardware, activations, and Ethernet Harnesses (availability dependent upon destination) |

| Remote diagnostics | Available with activated JDLink hardware and activations |

| Miscellaneous | |

| Country of manufacture | USA |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Tracks | |

| Drive type | |

| Midrollers | |

| Track width | |

| Tread spacing |

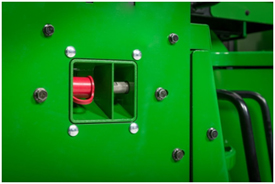

The rotary beacon light is installed to meet requirements in commercial or governmental applications. The rotating, high-intensity light rests securely within an amber-colored safety lens. Both the light and lens are replaceable if damaged.

The rotary beacon light features a fully adjustable, double-clamp design that provides a more rigid vertical support stem.

The rotary beacon light is installed to meet requirements in commercial or governmental applications. The rotating, high-intensity light rests securely within an amber-colored safety lens. Both the light and lens are replaceable if damaged.

The rotary beacon light features a fully adjustable, double-clamp design that provides a more rigid vertical support stem.

Right-hand window wiper

Right-hand window wiperOptional right-hand window wiper with washer fluid is available on standard and premium cabs. This option allows the operator to clean the window in dusty conditions from the comfort of the cab. The windshield wiper fluid tank is located on the operator platform near the front of the cab.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

A favorite worldwide, the RAM self-leveling cup holder is now available as a kit - designed specifically for Deere equipment. It is easily installed to keep your favorite beverage upright even in the roughest terrain. The perfect accessory for any cab that has 10-mm mounting bosses.

Self-leveling cup holder John Deere branded beverage insulator included

Self-leveling cup holder John Deere branded beverage insulator included

The new cup holder features a unique self-leveling design. This pivoting design allows easy adjustment for the holder while offsetting motion of the vehicle when moving.

Features and applications:

The producer can utilize various integrated technologies during sprayer operation and the following attachments allow them to properly fit, display, and charge these accessories:

This optional cross-gate joystick replaces fingertip paddle pots for control of selective control valves (SCVs) and allows for programmable hydraulic functionality according to operator preference.

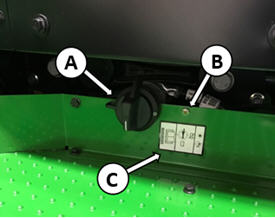

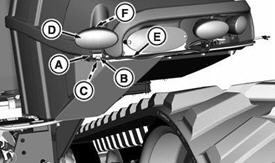

Battery disconnect installed

Battery disconnect installed

A. disconnection switch

B. yellow light-emitting diode (LED) indicator

C. reference label

Available as either a factory- or field-installed attachment, the battery disconnect switch is used to disconnect the batteries in preparation for 20-day to 90-day storage periods. The switch cuts the power to the entire tractor to aid in maintaining battery life.

An indicator light allows for safe and proper disconnect. The light will flash until it is safe to disconnect. This allows the diesel exhaust fluid (DEF) tank and lines to purge.

ISO 11783 location in R-Series Tractor cab

ISO 11783 location in R-Series Tractor cab RE322780 ISO cab implement CAN bus adapter

RE322780 ISO cab implement CAN bus adapterThe ISO cab implement controller area network (CAN) bus adapter is available to connect any ISO compliant implement or device to an 8R, 8RT, 9R, 9RT, 9RX (including Scraper Special) Series Tractor. These connectors are commonly used for planter frame control boxes.

Refer to the operator's manual, sections 16 (CommandCenter™) and 25 (Operator Station), for additional information on ISO implements.

NOTE: If the harness is not in use, unplug it from the ISO 11783 location or plug the 4-pin connectors together on the harness. If neither of these are done, implement CAN communication errors will occur.

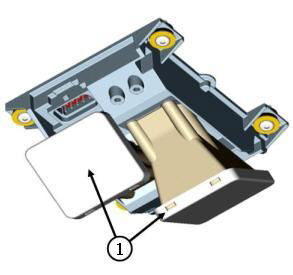

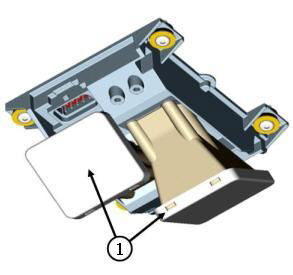

Dual-beam radar emission horns

Dual-beam radar emission horns  Dual-beam radar (tracks tractor shown)

Dual-beam radar (tracks tractor shown) Shield for dual radar beam

Shield for dual radar beamIn today’s agricultural environment, accuracy and precision are more important than ever. For something as basic as ground speed, operators need key information for precise control of various implements and the tractor. To support these needs, tractors can be ordered with a dual-beam radar unit as a factory- or field-installed option.

There are several key features that have changed from previous designs.

First, there are two horns for exit of the radio beam. This dual-beam design assures a powerful and accurate signal that will cut through interference that at times makes single-beam units inaccurate. (See 1 in the image above for beam locations.) Dual-beam output makes radar less susceptible to hard surface or tall/wavy grass interference.

Accuracy is aided by a heavy-gauge mounting bracket and rubber isolators that reduce chances that vibration can affect the radio signal.

Dual-beam radar has a fast update rate. When the tractor comes to a stop, accelerates, or varies speed, the indicated ground speed on the tractor display will closely match the actual ground speed. This is important for implements that use radar speed to control operation such as planters, seeders, fertilizer applicators, and sprayers.

In addition, the dual-beam radar does not require calibration to assure accuracy. Its self-calibrating ability is sure to save setup time by elimination of a special procedure that was required in the past.

The radar true ground speed sensor activates the following CommandCenterTM display or performance monitor readouts:

Radar usage improves the accuracy of the following CommandCenter or performance monitor functions:

Dual-beam units are compatible with controller area network (CAN) bus and International Organization for Standardization (ISO) bus electrical systems.

Dual-beam radar emission horns

Dual-beam radar emission horns  Dual-beam radar (tracks tractor shown)

Dual-beam radar (tracks tractor shown) Shield for dual radar beam

Shield for dual radar beamIn today’s agricultural environment, accuracy and precision are more important than ever. For something as basic as ground speed, operators need key information for precise control of various implements and the tractor. To support these needs, tractors can be ordered with a dual-beam radar unit as a factory- or field-installed option.

There are several key features that have changed from previous designs.

First, there are two horns for exit of the radio beam. This dual-beam design assures a powerful and accurate signal that will cut through interference that at times makes single-beam units inaccurate. (See 1 in the image above for beam locations.) Dual-beam output makes radar less susceptible to hard surface or tall/wavy grass interference.

Accuracy is aided by a heavy-gauge mounting bracket and rubber isolators that reduce chances that vibration can affect the radio signal.

Dual-beam radar has a fast update rate. When the tractor comes to a stop, accelerates, or varies speed, the indicated ground speed on the tractor display will closely match the actual ground speed. This is important for implements that use radar speed to control operation such as planters, seeders, fertilizer applicators, and sprayers.

In addition, the dual-beam radar does not require calibration to assure accuracy. Its self-calibrating ability is sure to save setup time by elimination of a special procedure that was required in the past.

The radar true ground speed sensor activates the following CommandCenterTM display or performance monitor readouts:

Radar usage improves the accuracy of the following CommandCenter or performance monitor functions:

Dual-beam units are compatible with controller area network (CAN) bus and International Organization for Standardization (ISO) bus electrical systems.

7030 Series Large-Frame Tractor shown

7030 Series Large-Frame Tractor shownThe severe-duty water separator factory-installed option or field-installed kit is available for locations where fuel quality can at times be in question. This kit will extend service intervals and help protect the tractor fuel system from damage if the fuel contains more water than the base filtering equipment can handle on a continual basis.

The 60 micron constructed of stainless-steel filter element must be backflushed whenever the bowl is half full of water. The filter can be backflushed up to five times before the filter must be removed and cleaned. Filter element must be replaced when light is no longer visible through the filter. The replacement interval will vary depending on fuel quality.

7030 Series Large-Frame Tractor shown

7030 Series Large-Frame Tractor shownThe severe-duty water separator factory-installed option or field-installed kit is available for locations where fuel quality can at times be in question. This kit will extend service intervals and help protect the tractor fuel system from damage if the fuel contains more water than the base filtering equipment can handle on a continual basis.

The 60 micron constructed of stainless-steel filter element must be backflushed whenever the bowl is half full of water. The filter can be backflushed up to five times before the filter must be removed and cleaned. Filter element must be replaced when light is no longer visible through the filter. The replacement interval will vary depending on fuel quality.

Front weight support

Front weight supportThe front frame weight bracket kit allows the tractor to be ballasted with up to 20 37 kg (104 lb) suitcase weights (R127764) for wheel tractors and up to 26 37 kg (104 lb) suitcase weights (R127764) for track tractors on the front frame.

The front weight frame and 20 37-kg (104 lb) weights are recommended on scraper designated tractors with flotation tires or when more front weight split is required.

IMPORTANT: Do not exceed 22,680 kg (50,000 lb) when ballasting 9030T Series Track Tractors.

Weight transfer to front axle and reduction to rear axle weight | ||

| | Front axle | Rear axle |

Front weight frame

| +272.2 kg (600 lb) | -61.2 (135 lb) |

| 20 weights and support | +1714.6 kg (3780 lb) | -739.4 kg (1630 lb) |

| Total | +1986.7 kg (4380 lb) | -800.6 kg (1765 lb) |

It is recommend that the front axle reinforcement kit be installed on all tractors equipped with any type of front ballast.

IMPORTANT: The front frame weight bracket is not intended to be used for pushing other tractors or implements and should not be used for securing chains or cables as tow points.

Kit shown in green mounted on gray main frame

Kit shown in green mounted on gray main frameThe front ballast bracket is optional from the factory using order code 8955. In some applications and conditions, it is beneficial to add additional front ballast to offset loads and/or gain additional traction. This kit creates provision to add up to 36 suitcase weights (R127764).

Adding weight to the front of the machine may also require the installation of front axle reinforcement kit factory order code 8041, or field installed BRE10198.

On machines equipped with tow cables, this kit may interfere and require adjustment or additional parts for the tow cable to mount correctly to the front of the machine. Reference the part catalog for additional information.

Note: This is a noncurrent kit. The information provided is valid for each tractor as of the last date that tractor was in production.

Quik-Tatch weights are used to better ballast tractors for both field and loader applications.

Applies to tractor models:

R129660 - Quick-Tatch Weight

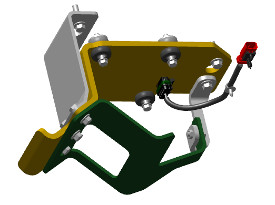

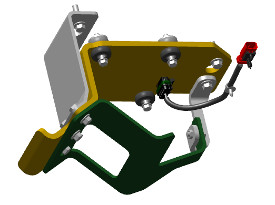

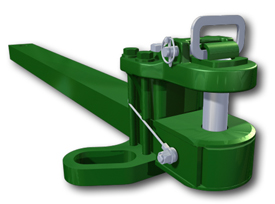

R129660 - Quick-Tatch Weight 9RT rear hydraulics

9RT rear hydraulics CommandARM™ SCV controls

CommandARM™ SCV controlsHigh-flow fifth and sixth SCVs provide additional hydraulic flow for use with triple scraper pans.

Five remote SCVs

Five remote SCVsThe field-installed electronic SCV kits are made available for tractors needing additional SCVs. These kits provide metered flow rates and timed detents with pressure and load sense compensation. The additional SCV(s) can also be integrated into the Headland Management System.

The field-installed kit includes International Organization for Standardization (ISO) lever-assisted breakaway couplers and armrest control lever.

A rear fender rear facing work light is available for your tractor. The kit comes with mounting hardware and a harness which directly connects to your tractors existing harness.

This mounting location allows for illumination of your hitch and drawbar area to aid on making connections to your implement with natural lighting conditions are poor.

John Deere CommandView™ III cab offers several options for outside mirrors to increase rear visibility to assist in getting the view needed of variable-width implements, wagons, or carts. The wide-angle mirror options provide excellent overall rear visibility and are easily adjusted and telescope to maintain visibility for a variety of implements.

7R and 8R Series Tractor mirror options:

8RT Series Tractor mirror options:

9R and 9RX Series Tractor mirror options:

9RT Series Tractor mirror options:

Field-installed kits are also available to convert a manual mirror to an electrically adjustable mirror. See the attachment section for further information.

NOTE: Left-hand electrically telescoping mirrors are not compatible with 8RT and 9RT Tractors.

Manually adjustable, single pane mirrors

Manually adjustable, single pane mirrors Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series Tractors

Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series Tractors

John Deere CommandView™ III cab offers several options for outside mirrors to increase rear visibility to assist in getting the view needed of variable-width implements, wagons, or carts. The wide-angle mirror options provide excellent overall rear visibility and are easily adjusted and telescope to maintain visibility for a variety of implements.

7R and 8R Series Tractor mirror options:

8RT Series Tractor mirror options:

9R and 9RX Series Tractor mirror options:

9RT Series Tractor mirror options:

Field-installed kits are also available to convert a manual mirror to an electrically adjustable mirror. See the attachment section for further information.

NOTE: Left-hand electrically telescoping mirrors are not compatible with 8RT and 9RT Tractors.

Manually adjustable, single pane mirrors

Manually adjustable, single pane mirrors Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series Tractors

Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series Tractors

John Deere CommandView™ III cab offers several options for outside mirrors to increase rear visibility to assist in getting the view needed of variable-width implements, wagons, or carts. The wide-angle mirror options provide excellent overall rear visibility and are easily adjusted and telescope to maintain visibility for a variety of implements.

7R and 8R Series Tractor mirror options:

8RT Series Tractor mirror options:

9R and 9RX Series Tractor mirror options:

9RT Series Tractor mirror options:

Field-installed kits are also available to convert a manual mirror to an electrically adjustable mirror. See the attachment section for further information.

NOTE: Left-hand electrically telescoping mirrors are not compatible with 8RT and 9RT Tractors.

Manually adjustable, single pane mirrors

Manually adjustable, single pane mirrors Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series Tractors

Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series TractorsAutoLoad is exclusive to John Deere and is a major innovation in the earthmoving industry. It allows novice and experienced operators to be more consistent and productive while operating John Deere tractors and scrapers. With the touch of a button, operators maximize productivity and efficiency even if they have never operated tractors and scrapers.

The system includes a draft sensor on the drawbar, radar for measuring wheel slip, position sensors on the scrapers, AutoLoad CommandCenter™ console, and a controller that analyzes the inputs from all sensors and controls the scraper operation during the loading cycle, providing consistent productivity.

Mounting brackets are available to mount a standard ABC extinguisher to your tractor. The bracket mounts to the entrance platform at the top of the entrance/egress steps on 9R series tractors.

This location allows quick access to the extinguisher near the cab door, should it ever be needed.

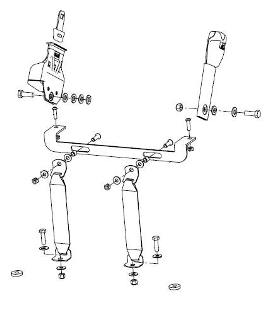

Hydraulic hose support

Hydraulic hose support

This field-installed option reduces stress on the couplers by providing support to the heavy hydraulic hoses used in scraper application. The hydraulic hose support attaches to the back of the tractor next to the drawbar and is available on all 9R, 9RT and 9RX Scraper Tractors.

Custom key door lock kit

Custom key door lock kitField-installed kit (AL71345) allows for a door handle to be installed that has a key different from the tractor ignition key.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Tow cable front hook

Tow cable front hook Rear tow cable connection point

Rear tow cable connection pointThe front tow cable is recommended for pulling all 9 Family Tractors in time of needed assistance. Tow cables are available as a factory-installed option on all ag tractors and are base equipment on all Scraper Special Tractors. The tow cable attaches to the area in front of the drawbar and is also available as a field-installed option.

Tow cable front hook

Tow cable front hook Rear tow cable connection point

Rear tow cable connection pointThe front tow cable is recommended for pulling all 9 Family Tractors in time of needed assistance. Tow cables are available as a factory-installed option on all ag tractors and are base equipment on all Scraper Special Tractors. The tow cable attaches to the area in front of the drawbar and is also available as a field-installed option.

Accessories mounting bracket

Accessories mounting bracket Tray kit

Tray kitThe accessories bracket is available for mounting monitors, phones, radios, and other accessories in one convenient location.

The bracket connects in the existing holes inside the cab.

This kit provides antenna mount, radio mounting plate, and wiring for a business band radio.

Backup alarm on a 9R Series Tractor

Backup alarm on a 9R Series Tractor

To better accommodate governmental or commercial sales, a back-up alarm is available as a factory- or field-installed attachment on select models. An alarm sounds whenever the transmission is placed in reverse. The alarm provides a high level of warning that the tractor is changing direction.

A backup alarm is base equipment on 9R and 9RT Scraper Special Series Tractors.

The floor insulation kit can reduce cab heat generated by transmission and hydraulic oil temperatures below the cab floor. It can reduce the overall cab temperature, as it works as a thermal barrier. The product comes in a large sheet, which is easily cut to fit the contours of the cab floor.

The kit is large enough to fit the floor pan design of 6 through 9 Series Tractor cabs.

This kit replaces the rear upholstery behind the operator seat with an additional panel containing a grille screen and base speaker. It allows the tractor to reproduce a deeper range of base tones with seamless installation. The clean look and powerful sound adds a level of comfort and enjoyment for long days in the cab.

Radio

RadioJohn Deere radio packages provide powerful performance with standard four-speaker systems. The standard radio package features easy-to-use operator controls located on the CommandCenter™ display and at the radio faceplate. AM/FM and weatherband tuner allows operators to stay tuned to their favorite radio stations and keep current with ever-changing weather patterns. An auxiliary input for connecting an external media source is conveniently located on the right-side console.

The premium radio package adds to these great features with Bluetooth® to connect with compatible media devices and a USB input for connecting external media sources. A subwoofer is also available in this package to increase the operator experience within the cab.

Both radio packages help create a comfortable operator environment for long hours in the cab.

*XM Satellite functionality for premium radio needs to be upgraded by purchasing the XM antenna, XM receiver, brackets, and wiring harnesses via a kit from your local John Deere dealer.

Radio controls

Radio controlsBosch is a trademark of Robert Bosch GmBH. Bluetooth is a trademark of Bluetooth SIG Incorporated. XM is a trademark of XM Satellite Radio Incorporated. Delco is a trademark of General Motors LLC.

Conversion kit

Conversion kitA Category 5 to Category 4 drawbar conversion kit is available for operators who have Category 4 implements that cannot be converted to Category 5.

The preferred method when operating high-horsepower tractors is to convert implements to Category 5.

For additional implement information, please reference the planting and seeding or the tillage information.

Rear-wheel weight

Rear-wheel weight

Cast-iron wheel weights provide added ballast at the tires for increased traction and stability.

Seat belt for 8R Series Tractors

Seat belt for 8R Series TractorsThe 3-in. field-installed seat belt kit is designed for use with the 8R and 8RT Series Tractor operator seats. The seat belt kit is offered to meet regulations that require a seat belt anchorage force similar to the SAE J386 (including previous versions up to 22.2 kN anchorage strength), IOS 6683, and OSHA requirements (29CFR1926.602) for earthmoving operations and non-agricultural tractor operations.

NOTE: John Deere recommends reviewing the seat belt kit performance capabilities to ensure compliance with local, state, regional, and national requirements.

Rear-wheel weight

Rear-wheel weight

Cast-iron wheel weights provide added ballast at the tires for increased traction and stability.

72-kg (159-lb), 205-kg (452-lb), 625-kg (1378-lb), and 970-kg (2138-lb) cast rear-wheel weights are available for the 7R and 8R Series Tractors. The attaching hardware for all rear-wheel weight options may be ordered through parts.

The range of rear-wheel weights can provide the proper amount of rear axle ballast for a variety of applications. The addition of this ballast will increase traction on the rear axle of the tractor. These weights can also be used to counterbalance the effect of adding additional weight on the front axle in the form of a front weight support, front hitch, front spray tanks, and front-end loaders.

72-kg (159-lb) starter weight

The 72-kg (159-lb) cast rear-wheel weight is offered individually as attachment R167153. This weight can be used either as an inner or outer rear-wheel weight. The 72-kg (159-lb) weight can be used by itself or as a starter weight for the 205-kg (452-lb) rear-wheel weights.

205-kg (452-lb) weight

The 205-kg (452-lb) cast rear-wheel weight is offered individually as attachment R07782. The 72-kg (159-lb) starter weight (R167153) must be installed prior to the 205-kg (452-lb) weight on rear steel wheels. This practice is optional on cast wheels; however, most weight packages will be configured this way.

625-kg (1378-lb) weight

R553540 includes one 625-kg (1378-lb) cast inner rear-wheel weight. This weight is to be used on the inside of the rear wheel assembly. This option can be stacked on a double-flat cast hub, with a 70-kg (154-lb) starter ring on the outside.

70-kg (154-lb) weight

BRE10026 features a 70-kg (154-lb) starter weight. The starter weight and guide lugs provide improved installation and removal of the 900-kg (1984-lb) weight. This weight can be used individually on the outside of the steel, dual rims on rack-and-pinion axles, or on the outside of the double-flat, single-taper wheel hub. For the approved cast hubs, can also be used with the inner cast weights as well.

NOTE: Use on the outer side of approved cast hubs will limit dual tire and spacing capability.

900-kg (1984-lb) weight

Individual R341378 900-kg (1984-lb) weights ordered through Parts. The 70-kg (154-lb) starter weight is required for installation, and provides guide lugs for improved installation and removal of the 900-kg (1984-lb) weight. 900-kg (1984-lb) weight ballast option is compatible with steel, dual wheels with rim diameters of 106.7, 116.8 cm, or 127 cm (42 in., 46 in., 50 in., or 54 in.). This allows the weights to be added to only the outer rear dual on a rack-and-pinion axle and double-flat axle with single-taper hub.

NOTE: This weight option is not compatible with 96.5-cm or 137.2-cm (38-in. or 54-in.) wheels.