We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

SeedStar 4HP is designed to optimize the in-cab monitoring experience exclusively on the Gen 4 4600 CommandCenter™ display or 4640 Universal Display for growers with ExactEmerge™ planters and MaxEmerge™ 5e planters model year 2018 and newer. With SeedStar 4HP, operators will easily see key planter information with customizable run pages, zoom functionality, and simultaneous graph and performance measurements. SeedStar 4HP is included in base on all model year 2018 ExactEmerge and MaxEmerge 5e planters.

Features overview:

SeedStar 3 HP conversion to SeedStar 4HP with mobile row-unit runoff aftermarket for field conversion kits

Growers who are currently running model year 2017 planters, model year 2017 and newer retrofit kits, or model year 2017 and newer custom-built planters with the SeedStar 3 HP monitoring system can upgrade to the SeedStar 4HP monitoring system with mobile row-unit runoff. The attachment part, AA100382, is software only. The Gen 4 display software version will need to be 19-1 or newer and will require planter apps. Follow the mobile runoff ordering and software push guide below for ordering and installation. Retrofitted planters and custom-built planters will also require the John Deere Connect Mobile kit, 0048PC, from the Precision Ag Technology Price Pages and wiring harness AA83662 to enable the mobile row-unit runoff feature. Please reference Parts Advisor and CCMS Solution 105181 for model-specific mounting brackets. SeedStar 4HP requires the Gen 4 4600 CommandCenter™ v2 display or 4640 Universal Display.

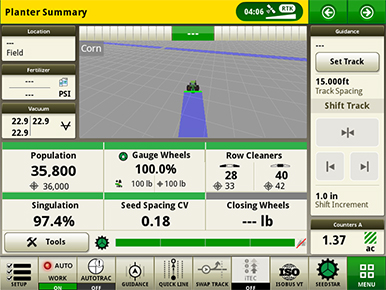

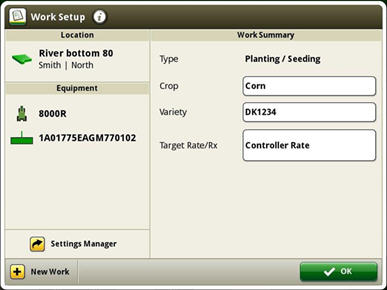

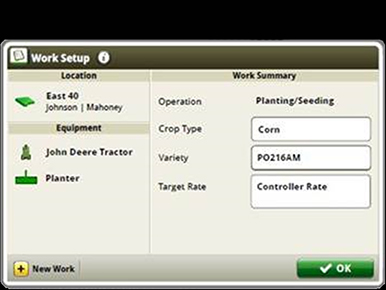

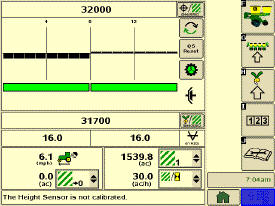

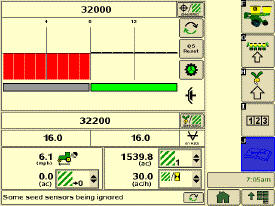

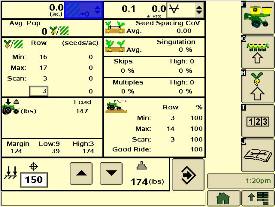

Planter summary default run page

Planter summary default run page Planter overview default run page

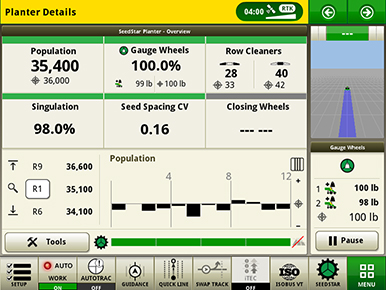

Planter overview default run page Planter details default run page

Planter details default run pageThree default run pages show key planter functions in different views to give fast and easy access to important planter information.

Customizable run pages

Customizable run pagesThere are customizable run pages that allow the operator to build pages that fit their operation with different modules, like the example shown above.

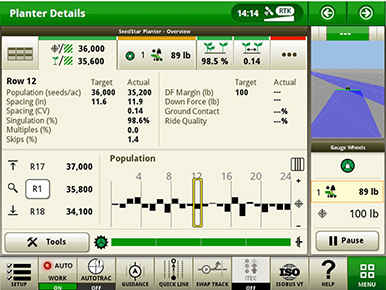

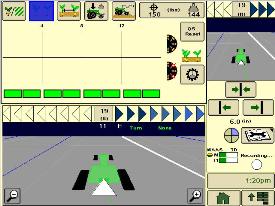

Zoom feature showing a group of rows

Zoom feature showing a group of rows Zoom feature showing a single row

Zoom feature showing a single rowThe zoom feature allows the operator to touch a section or row of the planter and get detailed information quickly.

Dual bar graph showing singulation and population simultaneously

Dual bar graph showing singulation and population simultaneouslyDual bar graphs allow operators to view multiple planter details at one time.

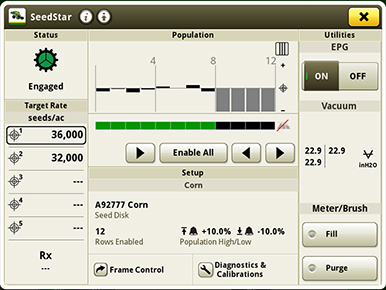

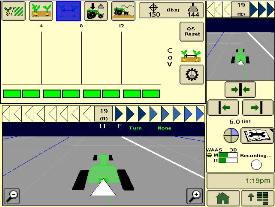

SeedStar application run page

SeedStar application run pageIn the SeedStar application, many adjustments can be made, including manually activating section control. SeedStar 4HP allows up to 48 individual row sections. There are several setup features such as crop, seed disk, number of rows being planted, population alarms, and limits. Seed rates can be modified, electric power generation (EPG) can be turned on or off, vacuum can be adjusted, and the fill and purge functions can be used from the SeedStar application. Frame control, as well as diagnostics and calibrations, can be accessed at the bottom of the screen.

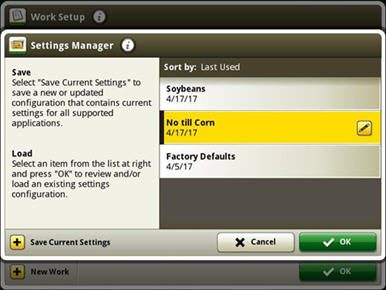

Settings Manager screens

Settings Manager screens

Reduce set-up time between changing crops or field conditions by recalling saved settings used previously with Settings Manager, included with every SeedStar 4HP system. This feature allows saving and recalling planter and tractor settings for optimum performance in different conditions.

Settings Manager can be used to save all of the adjustment and inputs associated to a particular crop or condition. An example would be to store all population rates, downforce pressure, row cleaner adjustments, and closing wheel settings for planting corn and storing a separate, unique set of adjustments for soybeans. In addition, Settings Manager stores tractor settings such as selective control valve (SCV) flow and detents, infinitely variable transmission (IVT™) settings, eco modes, and more.

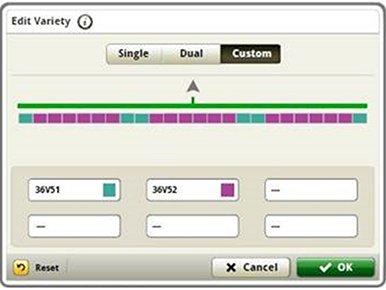

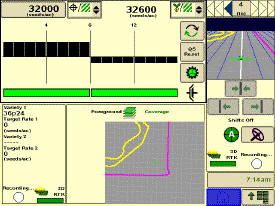

Variety set-up page

Variety set-up page Rate set-up page

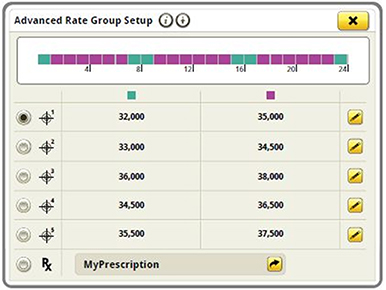

Rate set-up page Group rate set-up page

Group rate set-up pageCustom rates allow for individual row population control and row-by-row documentation where up to six different rates can be assigned across an up to 48-row planter. This allows growers interested in planting seed corn with ExactEmerge or MaxEmerge 5e the capability to assign specific populations to male and female rows for planting. This feature can also be used to create tram lines or other applications where custom rates by row are needed.

NOTE: Individual rates are tied to varieties, so each individual rate needs a unique variety name.

| SeedStar 4HP compatibility | |

| Planters | All models ordered with ExactEmerge or MaxEmerge 5e row-units NOTE: Retrofit kits are equipped with SeedStar 3HP only, but can be upgraded by purchasing part number AA100382. |

| Displays | Gen 4 4600 CommandCenter equipped with Version 2 Processor or 4640 Universal Display Dual-display mode is compatible with mid model year 2019 planter software. |

| Active Implement Guidance (AIG) | Compatible with SeedStar 4HP on Gen 4 displays with VT mode and required activations and subscriptions |

| AutoTrac™ Implement Guidance | Not compatible |

| AutoTrac Turn Automation | Not compatible |

For additional information on feature functionality on the Gen 4 Display, visit the links below:

YouTube is a trademark of Google LLC.

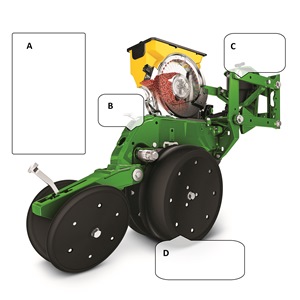

Heavy-duty adjustable downforce spring

Heavy-duty adjustable downforce springPlanter row-unit downforce is an important factor to ensure consistent and proper depth control. The heavy-duty adjustable downforce feature provides up to 181.4 kg (400 lb) of downforce. There are four settings available to allow the operator to choose the amount of downforce required for the condition: 0 kg (0 lb), 56.7 kg (125 lb), 113.4 kg (250 lb), and 181.4 kg (400 lb).

Compatibility: 1705, 1715, 1725, 1735, 1755, 1765, 1765NT, 1775 Flex, and 1785

Pneumatic downforce provides convenient, simple adjustment of downforce for the whole planter from one location. The amount of downforce applied is infinitely adjustable from 0 to 181.4 kg (0 to 400 lb). Pneumatic downforce provides more consistent downforce throughout the range of row-unit travel than mechanical spring downforce systems.

Features include:

Pneumatic downforce spring

Pneumatic downforce springEach row-unit has a single rubber air bag located between the parallel arms. The air bags are hooked in parallel so that air can be added or released from all rows at once from one location.

The individual pneumatic downforce air bag assemblies, air compressor units, and 9.5-mm (3/8-in.) delivery lines are also available as an attachment for field conversion.

Pneumatic downforce compressor and gauge

Pneumatic downforce compressor and gaugeAn improved compressor is used to charge the pneumatic system. This compressor can be located on the planter frame or in the tractor cab if desired. A gauge at the compressor indicates the amount of downforce being applied.

From the factory, integral planter models with pneumatic downforce will have an improved air compressor assembly with an in-cab mounting bracket, except for the 1725 16-row and 1725 Central Commodity System (CCS™) twin-row planters, which will have the air compressor assembly mounted on the planter frame. For drawn planter models, the 1755, 1765, 1765NT, 1775 Front-Fold, and 1785 Drawn Planters will have the air compressor assembly installed either on the outer hitch or wing frame members when the pneumatic downforce system is installed.

Base equipment on: 1705, 1715, 1725, 1735, 1755, 1765, 1765NT, 1775 and 1785.

The functional features of the integrated system are the same as the standard pneumatic system, explained above, with the addition of control through the GreenStar™ display.

Pneumatic downforce control in GreenStar 2 Display

Pneumatic downforce control in GreenStar 2 Display Air compressor mounted on 1775NT outer hitch

Air compressor mounted on 1775NT outer hitchOn 1725 16-row, 1725 CCS TR, 1775NT, 1775NT CCS, 1795, DR, and DB Series Planter models, the air compressor will be mounted on the outer hitch or frame assembly. Since the air compressor assembly is mounted on the outer hitch (as noted in the picture above) or frame, adjustments for row-unit downforce and related system pressures will be made electronically with the GreenStar display.

When adjusting the amount of row-unit downforce using the GreenStar display, the operator will select the amount of downforce (kg [lb]) to be applied across the planter. Depending on the soil conditions at hand, the operator might need to adjust the relative amount of row-unit downforce being applied during the planting operation. The integrated pneumatic downforce controls within the GreenStar display will only allow for set-point operation and not automatic control as the planter is operating in different soil conditions. The pneumatic downforce system does not have the capability to automatically adjust downforce.

Onboard air storage installed on 1775NT 24R30

Onboard air storage installed on 1775NT 24R30The 1725 16-row, 1725 CCS TR, 1775NT, 1775NT CCS, 1795, DR, and DB Series planters will have onboard air storage to increase the overall response time when making a row-unit downforce adjustment from the GreenStar display. The onboard air storage is comprised of a 18.9-L (5-gal.) storage tank with valve assembly.

Base equipment on: 1725 CCS, 1725 16-row, 1725T, 1775NT, 1775NT CCS, 1795, DR, and DB Series Planters with MaxEmerge™ 5 row-units. MaxEmerge 5e and ExactEmerge™ equipped planters come with active pneumatic downforce in base.

Active downforce compressor assembly

Active downforce compressor assembly Hydraulic motor

Hydraulic motorA hydraulically driven compressor works with the SeedStar™ 3 HP system and SeedStar XP system to automate downforce control. Just set the row-unit target margin value and the active pneumatic downforce system works automatically. The system will make sure the planter maintains this value, achieving precise soil penetration, and consistent planting depth, without sidewall soil compaction. From the factory, the system is set at 45.4 kg (100 lb) target downforce margin, but may be modified for varying field conditions. This frees the operator from constantly making manual downforce adjustments as conditions change.

This system offers a split-rank control feature for 1795 and DB Split-Row Planters. On split-row planters, active downforce will control the front and rear rows independently. This compensates for differing downforce requirements between the ranks that can be caused by things like different tillage or insecticide attachments and will help maintain an accurate planting depth and consistent margin across all the rows.

Active pneumatic downforce is available as factory installed or as an attachment for field conversion.

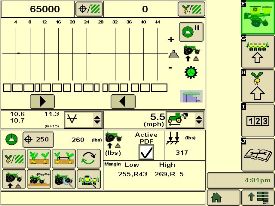

SeedStar XP downforce planter run page

SeedStar XP downforce planter run pageActive downforce control is integrated into SeedStar XP and SeedStar 3 HP monitoring systems.

Margin is the amount of weight riding on the depth gauge wheels that ensures desired firming of the seedbed as set by the operator.

Once a target margin has been defined, enter the value into SeedStar XP or SeedStar 3 HP and let active downforce do the rest. The system will actively adjust the air pressure in the air bags to maintain a constant margin across the planter. The changes in air pressure will change the amount of downforce placed on the row-unit, compensating and reacting for varying conditions through the field whether it is different tillage practices, soil types, or moisture.

Downforce and margin example

Downforce and margin example Hydraulic motor

Hydraulic motor Pneumatic valve

Pneumatic valveThe hydraulically driven air compressor can deliver up to eight times the air flow, allowing for more and faster downforce changes to be made. This more robust design features a 37.8-L (10-gal.) storage tank across all models with active downforce.

At approximately 15.1 L/min (4 gpm), hydraulic demands are low and ties into the machine’s lift and CCS hydraulic circuit so it does not require any additional selective control valves (SCVs). The SeedStar XP and SeedStar 3 HP monitoring systems work with the compressor and valve assembly to regulate air to downforce springs, enabling the active control.

Another feature of John Deere active downforce is the ability for the pneumatic valve to independently control split-rank machines. This system senses the downforce needs from the front and rear ranks separately and independently adjusts air pressures with the dual-rank pneumatic valve when equipped. Active pneumatic downforce requires SeedStar XP or SeedStar 3 HP to enable active control.

Base equipment on: All MaxEmerge 5e and ExactEmerge equipped planter models.

IRHD has been specifically designed to meet the needs of producers that are looking to adjust to the toughest field conditions and provide maximum yield potential from field to field, season after season. IRHD works as a closed-loop downforce system that reacts quickly on an individual row basis to changing soil conditions supporting increased ground contact, which can lead to improved seed depth consistency. When setting planter downforce margin, the system will apply the needed downforce by row to maintain ground contact. From the factory, the margin will be set at 45.4 kg (100 lb), changes may be required based on varying field conditions.

The system allows operators to maintain gauge wheel ground contact leading to desired seed depth placement. IRHD can adjust five times per second and make adjustments of 45.4 kg (100 lb) in less than a second. The system has a total range of applied downforce from 22.7 kg (50 lb) to 204.1 kg (450 lb) and utilizes the power beyond circuit on the tractor. IRHD is 58 percent faster than the active pneumatic downforce solution. Fast reaction and increased ground contact can lead to improved emergence. With uniform emergence, some studies have shown a yield impact from 5 percent to 9 percent.

IRHD is controlled through the Gen 4 4600 CommandCenter™ Display or 4640 Universal Display with SeedStar 4HP. As shown below, operators can view ground contact or applied downforce using the toggle button.

IRHD screen showing the ground contact graph

IRHD screen showing the ground contact graph IRHD screen showing the applied downforce graph

IRHD screen showing the applied downforce graphOptional equipment on: 1775NT, 1795, DB, and Orthman custom models with MaxEmerge 5e and ExactEmerge row-units.

Pneumatic closing wheels are compatible with MaxEmerge™ 5e and ExactEmerge™ row-units. They are available on the following models from the factory: 1775NT, 1795, and DB60 models. The pneumatic closing wheels give operators the ability to adjust closing wheels in seconds without leaving the cab of the tractor.

Using the GreenStar™ 3 2630 Display, pneumatic closing wheels can be adjusted to 25 different positions. From the factory the system is setup with two sections, the outer wings and center frame. With this system, producers will see up to a 76 percent increase in consistent force applied at the closing wheel. Consistently applying the correct force at the seed trench is one of the key elements of supporting improved emergence. Studies show potential yield impact on corn from even emergence from 5 percent to 9 percent*.

NOTE: Pneumatic closing wheels can be purchased for existing MaxEmerge 5e and ExactEmerge planters as an aftermarket field kit. Both rubber tire and cast-iron closing wheels are compatible.

Access the pneumatic closing wheels attachment for field conversion (AFC) ordering guide to fit a 1725 CCS, 1775NT, 1795, or DB60 Planter.

*Planting Outcome Effects on Corn Yield: Doerge, Tom, Jeschke, Mark and Carter, Paul

Coulter combo row cleaner

Coulter combo row cleaner Easy Adjust row cleaner

Easy Adjust row cleanerEasy Adjust row cleaner and coulter combo provides a pneumatic row tillage solution that is controlled from the seat of the tractor.

Every decision to make an adjustment during spring planting reduces the acres planted per day and can increase or decrease profitability. An adjustment that can be overlooked is row cleaners due to planter size, difficulty to make the adjustment, and varying conditions across fields and time.

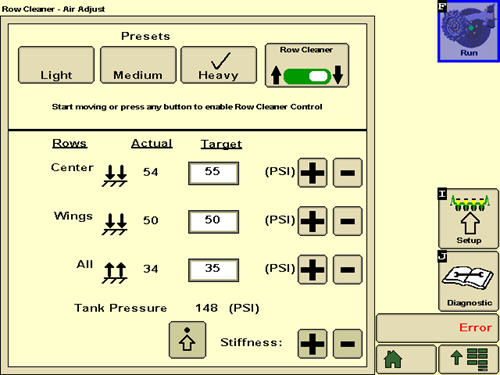

GreenStar™ 3 2630 Display view for row cleaners compatible with SeedStar™ 3 HP

GreenStar™ 3 2630 Display view for row cleaners compatible with SeedStar™ 3 HP 4600 CommandCenter™ Display and 4640 Universal Display view for row cleaners compatible with SeedStar 4HP

4600 CommandCenter™ Display and 4640 Universal Display view for row cleaners compatible with SeedStar 4HPWith the Easy Adjust row cleaners on ExactEmerge™ planters, operators now have a pneumatic solution to make on-the-go adjustments that is controlled directly from the seat of the cab. They can be raised from the cab as needed with the push of a button for wet areas, waterways, or end rows. For growers using SeedStar 3 HP, the row cleaners are completely integrated into the John Deere GreenStar 3 2630 Display as well as the Gen 4 4600 CommandCenter display or 4640 Universal Display. For growers using SeedStar 4HP, a 4600 CommandCenter display or 4640 Universal Display is required.

The Easy Adjust row cleaners have the capability to save three presets for varying ground engagement based on field conditions. The system is controlled in three sections: at each wing as well as the center (frame or wheel) track rows. The pneumatic lines use air from the active pneumatic downforce compressor, requiring no additional compressor to be installed on the planter. The Easy Adjust row cleaners utilize down and up force air bags. The adjustable air pressure setting for each bag allows the operator to set the ride of the row cleaner depending on the field conditions and the desired results. Making these on-the-go adjustments from tractor cab increases productivity and performance during planting.

For Easy Adjust row cleaner performance upgrade kit options, see the ordering guide.

The row cleaner-only option utilizes parallel linkage to provide the floating action growers require in their fields. Parallel linkage allows for the unit to float up and down in the situation of hills or hard objects. The cleaner and coulter combo does not have parallel linkage, however, the row cleaners have floating rings installed to help provide the same benefits.

The row cleaners utilize the field-proven SharkTooth® design. Row cleaners play a major role in maximizing yield toward uniform emergence, reducing row-unit bounce, and maintaining proper depth. The Easy Adjust row cleaners provide growers with quick and stress-free solutions to customizing the planter in variable field conditions. They are available on ExactEmerge and MaxEmerge 5e equipped planters. They are not integrated into the RowCommand™ feature.

SharkTooth is a trademark of Yetter Manufacturing Incorporated.

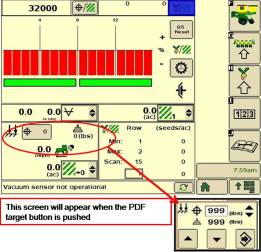

Vacuum automation screen

Vacuum automation screenVacuum control has been defined. Before vacuum automation, an operator set the vacuum level by adjusting the hydraulic flow through each selective control valve (SCV). Many variables altered the vacuum level while the hydraulic flow stayed constant. This could have resulted in under or over populating, which may have impacted singulation. With vacuum automation, all that needs to be done is set the desired vacuum level and let the monitor do the work of adjusting the hydraulic flow. Should vacuum changes occur, the software in the monitor will fluctuate the SCV flow to achieve the desired vacuum level.

Vacuum automation requires SeedStar™ 4HP monitoring. The system controls SCV flow based on the vacuum pressure sensor. The tractor must be a John Deere with Tractor Electronic Control Unit (TECU) 3 controller area network (CAN) system for this feature to be compatible. The vacuum automation feature will control all vacuum fans if they are on their own SCVs. More vacuum fans make the planter more valuable and easier to operate.

Vacuum automation is not compatible with Interim Tier 4 (IT4) 6R Series Tractors.

It is very challenging to get the crop planted during the optimum planting window or as close to the optimum planting day as possible. Rate-of-yield loss accelerates greatly after the optimum window has passed. This is especially true in the northern U.S. and Canada. ExactEmerge maintains accurate speed placement at higher speeds; growers can avoid missing that peak planting time, thereby helping to get the highest crop yields.

Yield loss after optimum planting day

Yield loss after optimum planting day

With the BrushBelt trench delivery system, the spacing in the trench does not change from even to uneven terrain. This can be a problem with a traditional seed tubes. Seed bounce and ricochet may occur as slopes increases, ultimately decreasing seed spacing performance.

The design of the BrushBelt system provides the best solution for the lowest release of seed to the bottom of the trench. The use of a brush provides the meter with an infinite amount of placement opportunities for each seed. This is what gives producers the confidence that every seed will have the desired spacing that a seed tube cannot provide.

Maintenance-free BrushBelt system

Maintenance-free BrushBelt system

When the brush comes around the pulley, it expands and allows the seed to be transferred from the bowl to the brush very easily. The brush then carries the seed down toward the trench, ensuring that there is no movement as it moves down the length of the cartridge.

Once the brush reaches the lower pulley, the BrushBelt system expands again to loosen the grip on the seed, and the centrifugal force releases the seed. Another advantage with the BrushBelt system and cartridge at all speeds up to 10 mph is the ability to match the seed rearward trajectory to the forward ground speed of the planter. This provides a dead drop of the seed with no bounce and no roll at the bottom of the trench.

BrushBelt conditioner engages brush bristles

BrushBelt conditioner engages brush bristles

John Deere’s ExactEmerge cartridge is self-cleaning. When an operator uses seed treatments or is forced to plant in less than ideal soil conditions, the design of the trench delivery system sheds buildup from the BrushBelt. A brush conditioner is located at the bottom of the cartridge to remove remaining residue and prevent the bristles from sticking together.

Brush proximity helps clean sensor

Brush proximity helps clean sensor

Another advantage over a seed tube is that the BrushBelt system also acts as a cleaner to the seed sensor compared to a seed tube.

BrushBelt removed from trench delivery system

BrushBelt removed from trench delivery system

The BrushBelt system requires no maintenance and has a wear life designed to match the wear life of the other wear components. Since operations vary, as do soils and field content, it is recommended to replace the BrushBelt after noticeable wear or decreased performance.

Changing the belt is easy. One latch removes the meter over the trench delivery system. Grab the cartridge by the grip and pull toward the body, releasing it from the electric motor fitting. Lift the trench delivery system up and remove the sensor wiring harness to completely pull the cartridge out of the row-unit.

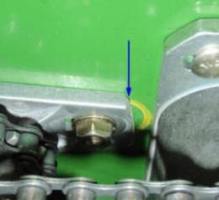

There are two plastic covers that snap off to uncover the belt; remove the covers and then twist the circular spring-tensioner dial with the yellow arrow on it to release the tension on the springs. Once tension has been removed, pull the belt out. It is also recommended to change the stainless-steel wear strip at this time as well, which also slides right out of place without the use of tools.

NOTE: It is recommended to use a talc/graphite mixture with ExactEmerge. Best results have been 80 percent talc and 20 percent graphite. For certain regions and territories, talc and talc/graphite mixes are restricted from use; in this case, use a wax-based fluency agent.

The MaxEmerge 5e is designed to improve population accuracy, spacing, and avoid wasting inputs for maximizing yield. The "e" in MaxEmerge 5e stands for electric drive. It is driven by one electric motor per meter with a small controller. This does away with the shafts and drivelines of a typical mechanical drive. That means more reliability, less maintenance, and easier access to row-unit components. For producers who want uniform seed spacing, the MaxEmerge 5e is a great option.

One of the biggest advantages of the MaxEmerge 5e is how it improves population accuracy by compensating for curves on the outer rows of the planter. The MaxEmerge 5e row-unit eliminates shafts and drivelines from the planter, allowing better access to row-unit components and decreased planter maintenance. Additionally, the MaxEmerge 5e allows corn and soybean growers to achieve up to a 20 percent improvement in population accuracy on the outer rows of a 24-row planter while planting on curves utilizing curve compensation.

While the MaxEmerge 5e uses a seed tube, it offers some of the same important advantages as ExactEmerge row units. The MaxEmerge 5e also improves reaction to population changes in the field when conditions dictate a higher or lower population, enabling producers to more accurately plant to the variable-rate prescription that maximizes profit potential. High-performance vacuum automation automatically maintains the target vacuum setting throughout the day with less time monitoring and making adjustments. It uses the SeedStar™ 4HP system and is compatible with Connect Mobile monitoring for near real-time, row-by-row planting performance. Depending on planter model, the MaxEmerge 5e package unlocks additional options like easy adjust row cleaners, individual row hydraulic downforce, and pneumatic closing wheels.

The MaxEmerge 5e delivery system options include mini-hoppers with Central Commodity System (CCS™), 56.4-L (1.6-bu) hoppers, and 105.7-L (3-bu) hoppers.

NOTE: MaxEmerge 5e row-units are compatible with the following models: 1725NT, 1725C, 1725 CCS (not available on twin row), 1775NT, 1795, DB44, DB60, DB66, DB80, DB88, and DB90 (not available on 54R 50.8 cm [20 in.]).

RowCommand on a MaxEmerge™ 5 row-unit

RowCommand on a MaxEmerge™ 5 row-unit RowCommand on a chain drive MaxEmerge 5 row-unit

RowCommand on a chain drive MaxEmerge 5 row-unitControlling input costs and improving productivity are key producer requirements today. RowCommand is an effective, integrated John Deere solution designed to meet these intensifying needs. The RowCommand system manages seed output, reduces yield drag, and improves harvest capabilities on all Pro-Shaft™ driven row-units, and chain-driven MaxEmerge 5.

NOTE: Chain-drive RowCommand is only compatible with planters equipped with pneumatic downforce systems. On planters equipped with the heavy-duty downforce springs, potential chain interference may result and is not recommended.

NOTE: Chain-drive RowCommand requires some modification to brackets in order to function with corn finger pickup meters.

NOTE: Pro-Shaft drive RowCommand is compatible on MaxEmerge 5 row-units with vacuum and corn finger pickup meters. For mini-hopper row-units, RowCommand is compatible on vacuum meters only and is not compatible on corn finger pickup meters. Pro-Series™ XP row-units with corn finger pickup meters are not compatible with RowCommand.

RowCommand controls seed output by incorporating individual, low amperage clutches inside the Pro-Shaft and chain-driven gearboxes. Clutches are completely enclosed within the gearbox housing to protect them from the elements and harsh operating conditions.

When power is supplied, either manually or through John Deere Section Control software, clutches disengage the seed meters and seed flow stops. Controlling seed output at individual rows reduces overplanting in point rows and maximizes seed placement when entering/exiting headlands.

Electronic power modules shown on a 1775NT Planter

Electronic power modules shown on a 1775NT Planter RowCommand clutch on MaxEmerge 5 with 105.7-L (3-bu) hopper

RowCommand clutch on MaxEmerge 5 with 105.7-L (3-bu) hopperRowCommand is a simple and efficient solution to control individual row planting. This system does not utilize air to operate; therefore, no compressor, air lines, or valve modules are required.

RowCommand utilizes low-voltage controller area network (CAN) messaging to signal power to the desired clutches to stop planting or eliminates power to resume planting.

This means very little power is used in normal planting conditions, and in the event a clutch fails electrically, the meter will continue to plant.

The RowCommand system requires the following five basic components to operate:

Clutches are protected within the sealed Pro-Shaft and chain-driven gearboxes for years of trouble-free operation and simple installation or removal. RowCommand has true individual-row control of up to 16 clutches or sections for planters larger than 16 rows.

Unique to RowCommand, the 16 available control sections can be configured based on operator preferences. For example, on a 1775NT 24-Row Planter, every two rows can be paired together for a total of 12 control sections, or control the outermost eight rows individually and the remaining inner rows paired together for 16 control sections.

While SeedStar with RowCommand has 16 control sections, a minimum of 152.4-cm (60-in.) wide sections are recommended for optimum Swath Control Pro™ solution capabilities. As with other Swath Control Pro products, an SF2 signal is the minimum level of accuracy recommend for operation.

RowCommand is available as a factory-installed option or as an attachment for field conversion attachments for the following Pro-Shaft drive planter models (see chart below).

| Planter model | Row configuration |

| 1725 | 12-row narrow, 12-row wide, and 16-row narrow |

| 1725 Central Commodity System (CCS™) | 16-row narrow |

| 1765 | 12-row narrow |

| 1775 | 12-row narrow |

| 1775NT | 12 row, 16 row, and 24-row narrow |

| 1775NT CCS | 12 row, 16 row, and 24-row narrow |

| 1795 | 12/23 row, 12/24 row, 16/31 row, and 16/32 row |

| 1795 | 24 row, 50.8 cm (20 in.) |

| DB 44 | 24 row, 55.9 cm (22 in.) |

| DB 58 | 32 row, 55.9 cm (22 in.) |

| DB 60 | 36 row, 50.8 cm (20 in.) or 47 row, 38.1 cm (15 in.) |

| DB 66 | 36 row, 55.9 cm (22 in.) |

| DB 80 | 32 row, 76.2 cm (30 in.) or 48 row, 50.8 cm (20 in.) |

| DB 88 | 48 row, 55.9 cm (22 in.) |

| DB 90 | 36 row, 76.2 cm (30 in.) |

| DB 120 | 48 row, 76.2 cm (30 in.) |

| DR (Deere/Orthman™ planter) 16R40 | 16 row, 101.6 cm (40 in.) |

| DR (Deere/Orthman) 18R38 | 18 row, 96.5 cm (38 in.) |

In terms of planter compatibility, RowCommand for chain drive is designed for the following planter model configurations equipped with pneumatic downforce systems.

| Planter model | Row configuration |

| 1725 | 12-row narrow, 12-row wide, and 16-row narrow |

| 1765 | 12-row narrow |

| 1775 | 12-row narrow |

| 1775NT | 12 row and 16 row |

| 1775NT CCS | 12 row and 16 row |

| DB 44 | 24 row, 55.9 cm (22 in.) |

Chain interference with heavy-duty downforce

Chain interference with heavy-duty downforceAs seen in the image, chain interference may result when operating chain-drive RowCommand on planters equipped with short and long parallel arms and heavy-duty downforce springs.

NOTE: Chain-drive RowCommand is only compatible with planters equipped with pneumatic downforce systems. On planters equipped with the heavy-duty downforce springs, potential chain interference may result and is not recommended.

Bracket material removal

Bracket material removalDue to the design characteristics of the chain-drive RowCommand clutch, some modification to the corn finger pickup meter drive bracket is required. As seen in the picture to the left, some material needs to be removed from the front of the meter drive bracket in order for the chain-drive RowCommand clutch to have sufficient space for installation.

NOTE: Chain-drive RowCommand requires some modification to brackets in order to function with corn finger pickup meters.

To add RowCommand to a model year 2009 and newer planter model listed above is simple. Pro-Shaft drive attachments for field conversion and chain-drive attachments for field conversion are available by planter model to add the appropriate number of clutches, EPMs, brackets, hardware and row-unit harnesses. For complete installation and part detail for the RowCommand conversion, please use the RowCommand compatibility tool per specific planter model.

RowCommand is compatible and available for model year 2003 (serial number 700101) to 2008 (725101) planter models listed above. In addition to the attachment for field conversion attachment, a planter mainframe harness, SeedStar 2 controller (wedge box), and additional CAN harnesses are needed.

Coupling RowCommand with Swath Control Pro provides the ultimate in precision planting and productivity. One company, one integrated solution are what we offer by incorporating Swath Control Pro capabilities within the SeedStar 2 wedge box (controller). Unlike previous systems, no rate controller, additional harnessing, or components are required to achieve automated individual-row control.

SeedStar 2 monitoring, RowCommand, and Swath Control Pro activation from John Deere Precision Ag Technologies are all that is needed when ordering.

RowCommand is a simple and efficient means to control individual row planting through the use of low-voltage electric clutches. When activated, each clutch consumes no more than 0.5 amps. By design, power is only supplied to the clutch when a signal is received to stop planting. In a normal planting condition, no power is supplied and the clutch is de-energized.

Power for the RowCommand system is provided from the 9-pin ISO implement connector. All late-model 8X00 and 9X00 Series John Deere Tractors equipped with the 9-pin ISO implement connector are capable of supplying ample power for system operation.

Along with ample system power, a GreenStar display and SeedStar monitoring are required for operation and control interface. The GreenStar display is where system setup, control settings, and manual control functions are performed.

Integrated innovation is what operators will appreciate with the SeedStar 2 monitoring system and GreenStar™ 2 Display. An increasing number of acres combined with rising seed costs drive the need to easily understand planter functions and monitor performance. It is all about making every seed count and that is what SeedStar 2 delivers.

The SeedStar 2 monitoring system is a full-feature, color, seed population monitor used in conjunction with the GreenStar family of displays. SeedStar 2 is compatible with the GreenStar 2 1800 and 2600 Displays, GreenStar 3 2630 Display, the Gen 4 4200 CommandCenter™ Display, the Gen 4 4600 CommandCenter Display, the 4240 Universal Display, and the 4640 Universal Display. SeedStar 2 is not compatible with the Gen 4 Extended Monitor. Conveniently, SeedStar 2 planting functions are fully integrated with the full spectrum of Precision Ag Technology applications—guidance, coverage maps, and field documentation can be shown all on one display.

When a SeedStar 2 system is used on a planter, there is no need for a ComputerTrak™ monitor. All vital planting information is displayed in one central, easy-to-read location.

SeedStar 2 full-screen planter run page

SeedStar 2 full-screen planter run pageSeedStar 2 is a user-friendly system that has retained all the valued features of SeedStar and incorporated the next generation of enhancements. For example, on-screen color indicators show drive engagement/disengagement status. In addition, three color planter-at-a-glance bars (black, orange, or red) visually inform the operator of row population status.

Not only does SeedStar 2 incorporate the use of color, it also utilizes an intuitive icon and folder based operator interface. Icons are easy to understand across many languages and reduce the need for text. Icons for planter main run page, planter setup, seed/crop setup, totals, and diagnostics are located in the soft-key region of the display. Setup is performed by selecting the appropriate icon and then choosing the tabs to enter/select information.

The SeedStar 2 monitor offers all of the features and functionality of the ComputerTrak 350 monitor and much more. SeedStar 2 monitors the following planter functions:

In addition, planter operational information is available within the SeedStar 2 monitor system. Such operational information includes population charts, seed disk vacuum settings, and setting recommendations for the piston pump liquid fertilizer system.

All SeedStar 2 systems have the capability, through a single controller, to perform both the seed monitoring and variable rate drive functions. SeedStar 2 monitoring is required for VRD population control. Even though the planter may not be equipped with SeedStar 2 VRD, the SeedStar 2 monitoring system is available and will allow for future installation of VRD.

SeedStar 2 half-screen planter run page

SeedStar 2 half-screen planter run page SeedStar 2 showing half-width disconnect status

SeedStar 2 showing half-width disconnect statusThe SeedStar 2 enhanced planter features include:

SeedStar 2 retains all those SeedStar features that producers value and have come to expect:

SeedStar XP shown on the GreenStar™ 3 2630 Display

SeedStar XP shown on the GreenStar™ 3 2630 Display SeedStar XP shown on the GreenStar 2 1800 Display

SeedStar XP shown on the GreenStar 2 1800 DisplayBuilding upon the foundation of SeedStar 2, the SeedStar XP system takes planter monitoring to the next level. SeedStar XP is compatible with the GreenStar 2 1800 and 2600 Displays, GreenStar 3 2630 Display, the Gen 4 4200 CommandCenter™ Display, the Gen 4 4600 CommandCenter Display, the 4240 Universal Display, and the 4640 Universal Display. SeedStar XP is not compatible with the Gen 4 Extended Monitor.

Specific information about how the planter is performing enables the operator to make needed adjustments for implement optimization.

The SeedStar XP planting functions are fully integrated with the full spectrum of Precision Ag Technology applications such as Swath Control Pro™ system for planters, GreenStar AutoTrac™ assisted steering system, John Deere Operations Center, Documentation, and others. Integrated planting technologies for better asset utilization and ease of use is just part of what SeedStar XP provides.

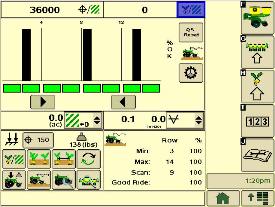

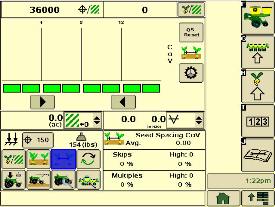

SeedStar XP seed singulation planter run page

SeedStar XP seed singulation planter run pageUnderstanding the meter singulation performance on the planter is critical to minimizing the amount of seed multiples and skips. As a result, the SeedStar XP monitoring system provides real-time information from the row-units about the overall seed singulation performance.

As seen in the screen shot image above, seed multiple information is displayed on the top portion of the planter-at-a-glance bar with seed skip information on the lower portion. This provides the operator a better understanding of relative seed multiple and skip data on a row-unit basis, all within one easy glance.

Also, within the seed singulation planter run page, information about row-units with the highest percentage of seed multiples and skips is provided in order to make necessary adjustments for better planter optimization.

SeedStar XP ride dynamics planter run page

SeedStar XP ride dynamics planter run pageWhile operating a planter, travel speed and field conditions can affect the amount of row-unit bounce that is experienced. Excessive row-unit bounce or vertical motion can cause problems with meter performance. To better understand the amount of row-unit vertical motion when travelling through a field, the SeedStar XP monitoring system provides real-time information on row-unit ride dynamics.

As seen in the ride dynamics planter-at-a-glance screen shot image above, the SeedStar XP system provides ride dynamic information for each sensor node that is mounted on the planter. Each sensor node transmits ride dynamic information for each planter frame section to allow for the operator to make necessary operating adjustments to improve overall planting performance.

SeedStar XP downforce planter run page

SeedStar XP downforce planter run pageAs row-unit downforce systems gradually change from heavy-duty downforce springs to pneumatic downforce, being able to understand the amount of as-applied row-unit downforce is needed while operating the planter.

With various soil conditions, moisture, etc. experienced while planting, it is imperative to have the ability to change actual row-unit downforce to have enough force for the Tru-Vee openers to penetrate the soil media. However, in some conditions, having too much downforce applied to the row-units for effective opener penetration could cause problems with side wall compaction from the gauge wheel.

Side wall compaction within the seed furrow can cause hatchet roots to develop, or roots that do not have the ability to penetrate the seed furrow soil media. This could lead to poor plant emergence and eventually lower overall yield performance.

With the SeedStar XP monitoring system, row-unit downforce information is measured by the downforce sensor and sensor nodes and transmitted to the GreenStar 2 Display in the tractor cab (as seen in the image above). The row-unit downforce information is displayed on the top portion of the planter-at-a-glance bar with more row-unit downforce information on the lower portion.

Two different control options are available on 1775NT, 1795, and DB Series Planters for pneumatic downforce. The base pneumatic downforce system requires manual control of the downforce to maintain the desired planting results or row-unit margin. Optional active pneumatic downforce takes SeedStar XP even further by removing constant downforce adjustments from the operator and actively controlling the downforce system to maintain a desired target margin.

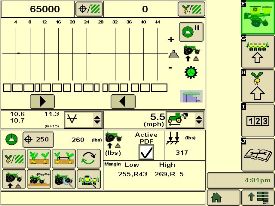

SeedStar XP seed spacing planter run page

SeedStar XP seed spacing planter run pageThroughout the planting process, obtaining good seed spacing is critical toward achieving plant growing conditions for maximum yield potential.

Today, many items are adjusted on the planter prior to planting to optimize overall seed spacing performance. After such adjustments are made, information about the actual seed spacing performance during planting was missing within the planter monitoring system. Now with SeedStar XP, seed spacing information is transmitted live via the GreenStar display to show the operator exactly what is happening with the planter behind them.

The SeedStar XP transmits seed spacing information onto the planter-at-a-glance bar for easy understanding of planter seed spacing performance. Also, information about seed skips and multiples is provided to help understand actual planter meter performance and other related system functions in order to make necessary adjustments if needed.

NOTE: Seed spacing and seed singulation information is only available when planting crops with seed drop rates below 40 seeds per second such as corn. With higher population crops such as soybeans the system does not provide spacing and singulation information because the number of seeds dropping per second is much higher.

SeedStar XP planter details

SeedStar XP planter details With the capability of monitoring differences in planting performance items such as seed singulation and row-unit downforce, having one screen to view all planter performance elements is needed to understand the whole planting system. SeedStar XP combines all of the various planting performance elements into one full-color, planter overview screen to enable for a quick understanding of relative planting functionality.

SeedStar XP seed singulation half screen

SeedStar XP seed singulation half screen SeedStar XP seed spacing half screen

SeedStar XP seed spacing half screenOther SeedStar XP monitoring features include:

SeedStar XP retains all of those SeedStar 2 features that producers value and have come to expect:

Planter main 2 controller

Planter main 2 controller Sensor node assembly installed

Sensor node assembly installedThe SeedStar XP monitoring system contains the following components in order to support the planting data transfer to the GreenStar 2 Displays:

The planter main 2 controller processes the row-unit data from the sensor node assemblies located on the row-unit head casting. The processed information is then sent to the SMVR controller to be integrated into the displayed information being sent to the GreenStar Display.

Downforce sensor assemblies are found on row-units with sensor nodes installed. The downforce sensor assembly is assembled with the gauge wheel depth-adjustment handle and provides gauge wheel pressure information to the respective sensor node for data processing.

Downforce sensor installed

Downforce sensor installed Downforce sensor assembly

Downforce sensor assemblyDepending on the planter size, different configurations of sensor nodes and downforce sensors are installed in support of the SeedStar XP monitoring system.

Variable-rate drive system

Variable-rate drive system

The variable-rate drive on the 12Row, 16Row, 18Row, and 24Row integral planter completing packages provide the ultimate planting productivity by utilizing three hydraulic motors to turn the seeding drive shaft. Hydraulic control of the seeding drive allows for on-the-go seeding rate changes right from the display mounted inside the tractor cab. Combine this seeding flexibility with the map-based planting option, and seeding rates adjust automatically based on a prescription map.

The variable-rate drive requires the SeedStar™ 2 monitor and a speed input signal. Either tractor or planter radar may be used, or a global positioning system (GPS) speed signal. The radar speed input signal is recommended. Planter radar is ordered separately.

The variable-rate drive offers the following advantages:

Three-width drive disconnect control

Three-width drive disconnect control

Three-width drive disconnect is base equipment on the custom 12Row, 16Row, 18Row, and 24Row integral planter completing packages. This feature is activated by three individual console mounted switches (control box), conveniently located in the tractor cab. The function easily shuts off the planter row-unit seed meters by one, two, or three drive segments independently.

Crop yields have increased through the years along with the amount of residue left in the field after harvest. At the same time, tillage practices have changed, including different tillage operations which maintain large amounts of surface residue, and even no-till practices. Row cleaners are an essential tool in managing this increased amount of residue.

John Deere seeding group offers a variety of row cleaner options to meet the needs of a producer's operation. Compatibility varies by model, row spacing, and other planter equipment.

Screw-adjust, unit-mounted row cleaner

Screw-adjust, unit-mounted row cleanerThe screw-adjust, unit-mounted row cleaner is mounted directly to the face plate of the row-unit, placing the ground engaging components just in front of the row-unit opener blades and depth gauge wheels. This close proximity allows the gauge wheels to control the depth of the row cleaner as well as the row-unit. This compact design also allows greater compatibility with fertilizer openers and other planter attachments.

SharkTooth® wheels are standard equipment on the unit-mounted row cleaner. The swept-tooth design of the wheel provides a clear path for the row-unit openers while resisting residue buildup on the wheel. The screw adjustment knob is accessible through the top of the parallel arms, providing convenient access for adjustments. The row cleaner can be adjusted in 1.6-mm (1/16-in.) increments, providing plenty of flexibility to meet the needs of changing conditions.

Floating row cleaner with unit-mounted coulter

Floating row cleaner with unit-mounted coulterThe floating row cleaner allows a row cleaner to be used in conjunction with a unit-mounted coulter. This combination is often desired in heavy residue loads and reduced tillage planting conditions. The row cleaner provides a clear path for the row-unit, while the unit-mounted coulter helps penetrate tough soil conditions.

Accommodating the unit-mounted coulter means the residue wheels are farther forward from the row-unit face plate than in the case of the screw-adjust row cleaner. To maintain performance, this row cleaner has the capability to float above a defined minimum depth.

Standard depth-gauging bands on the wheels allow the row cleaner wheels to float independently of the row-unit openers, allowing both to perform in varying terrain. The unit may also be set in a fixed position by simply pinning through the bracket if desired. This row cleaner also features SharkTooth wheels as standard equipment.

The floating row cleaner and unit-mounted coulters are available on many planters as factory-installed equipment. As compatibility and details vary by model, review the following links for information on specific planter models.

NOTE: Screw-adjust row cleaners are not compatible with MaxEmerge™ 5e row-units with long parallel arms.

NOTE: DB models have the option for either unit-mounted coulter, screw-adjust row cleaners, or pneumatic row cleaners (only compatabile with MaxEmerge 5e or equipped ExactEmerge™ models). The DB60T is only available with a less row cleaner option.

SharkTooth is a trademark of Yetter Manufacturing, Inc.