We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

A four-point independent suspension delivers a smoother, more comfortable ride. The W170 has four coil-spring shock absorbers working in conjunction with fore-aft and side-to-side stabilizers to minimize cab roll. The shocks are placed at each corner of the cab so the entire cab can go up or down from the resting position. This suspension makes the W170 one of the most comfortable cabs in the industry.

Draper visibility

Draper visibility Visibility to the entire platform

Visibility to the entire platformThe large, wide-front glass and cab positioned forward and above the platform give excellent visibility to the cutterbar and incoming crop across the widest platforms. This allows ease of operation and maximum productivity even in the toughest cutting conditions.

Lighting with beacon and light-emitting diode (LED) option

Lighting with beacon and light-emitting diode (LED) option Exterior lighting

Exterior lighting Rear lighting

Rear lighting Side/rear adjustable lighting

Side/rear adjustable lighting Lighting and markings

Lighting and markingsLED lighting is used to give the operator excellent visibility when operating at nighttime or in low-visibility conditions.

An optional HID lighting package is available with the base cab. Optional warning beacon lights are available, providing additional visibility during transport.

An optional reverser is available on the W170. It is easily activated from the operator’s station to clear the platform of plugs that may occur.

On the 1400D Draper Platforms, the reverser slowly reverses the knife drive and optional hay conditioner, if equipped, to clear plugs. The reverser is highly recommended when using the optional hay conditioner with the 1400D Platforms.

Attaching and detaching platforms is easy, allowing fast and narrow draper transport and the ability to quickly change from hay to grain harvest. This allows those with diverse operations to use the machine for more hours annually, spreading out their costs.

A hose management system is conveniently located in one spot, housing two hydraulic and one electrical connection.

Swing arm with connections

Swing arm with connections Connecting all hydraulic and electrical connections

Connecting all hydraulic and electrical connectionsHydraulic and electrical connections are compatible with the 400D Series draper heads, and 100A Series auger heads.

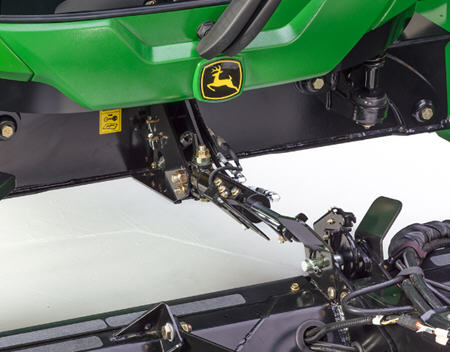

An optional self-alignment kit comes with the hydraulic center link, making attaching and detaching a breeze for those who move fields frequently or want the ease of attaching. This kit gives the capability to move the center link up and down with a cylinder under the cab controlled by the reel fore-aft buttons on the multifunction control lever.

Lower lift arms with draper boot attached

Lower lift arms with draper boot attached Quick-attach lower lift arms

Quick-attach lower lift arms Quick-attach 1100A Auger Platform

Quick-attach 1100A Auger Platform Quick-attach 1400D Draper platform

Quick-attach 1400D Draper platformThe pin on the lower lift arms allows for easy changeover from draper to auger platforms and also for changing from wide draper in-field operation to narrow transport.

Springs and float-fine adjust

Springs and float-fine adjustSprings are easily adjustable. Simply raise the platform to relieve spring pressure and turn the bolt to adjust the leverage on the springs. This allows changing platforms quickly and easily.

The float-fine adjust is in base equipment for the W170. It uses a small hydraulic cylinder to adjust spring length and force independently on each side. This also allows changing the platform float for varying field conditions on the go and has three memory positions from which to select. The float-fine adjust also allows rebalancing the platform when using the deck-shift feature by using the same controls on the armrest.

Transport wider draper platforms with ease and control using the ballast box and the 1400D with an integrated transport system.

Ballast box with seven-pin connector

Ballast box with seven-pin connector Transporting the 1435D

Transporting the 1435DIt also enables narrow transport when used with a 1400D Draper Platform with the integrated slow-speed transport system. The ballast box shifts weight onto the drive tires for traction and control when in transport. It also has a hitch for attaching and towing the 1400D Platform. It is required to have the electrical wiring harness and hitch pin kit to provide a seven-pin connector on the ballast box for lighting. This provides the W170 and 1400D Platform with visibility for safe transport.

W170 Self-Propelled Windrowers feature an AutoTrac Controller, delivering improved line acquisition and online accuracy to increase performance and lower cost of operation. The fully integrated AutoTrac Controller uses hydraulics to steer the machine, providing more precise control than the AutoTrac Universal solution.

Can be ordered from the factory

The W170 comes from the factory GreenStar™ system ready. Select the AutoTrac kit option when ordering the machine to make the W170 AutoTrac ready. The AutoTrac kit includes a hydraulic steering kit, AutoTrac Controller, and universal global positioning system (GPS) receiver mounting kit. An optional GreenStar 3 2630 Display kit and StarFire™ 6000 Receiver can also be ordered from the factory.

AutoTrac kit

The AutoTrac kit (dealer installed) includes:

NOTE: Estimated dealer install time for the AutoTrac kit is approximately 8 hours. Installation includes mounting and connecting the hydraulic and steering linkage components, installing the AutoTrac Controller, and installing the universal receiver mounting kit.

When ordered from the factory, the hydraulic kit will be shipped with the machine. The AutoTrac Controller kit and receiver mounting kit (and Greenstar 3 2630 Display and StarFire 6000 Receiver, if ordered) will ship from a secondary location separate from the machine.

Display (cornerpost mount)

The Greenstar 3 2630 Display includes:

Receiver

Compatibility and availability

AutoTrac Controller on W170 Self-Propelled Windrowers is compatible with the Greenstar 3 2630 Display and Greenstar 2 1800 Display. If not purchased from the factory at time of machine order, refer to the Precision Ag Technologies Sales Manual and Price Page for ordering information.