We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

John Deere rotary harvesting units are built for reliable and powerful feeding of high-capacity forage harvesters. Two fundamental designs are available to match all producer needs. The 600plus Series Headers are the universal solution for different crops up to 4-m (13.1-ft) tall. The 700plus Series Headers are the perfect solution for high-yielding crops.

772 Rotary Harvesting Unit

772 Rotary Harvesting UnitAvailable beginning in model year 2019, the top-model 772 12-Row Large-Drum Rotary Harvesting Unit has been designed to fully leverage the capacity of 9000 Series Self-Propelled Forage Harvesters (SPFH).

6X9 Series Windrow Pickup

6X9 Series Windrow PickupThe 6X9 Series Pickups with the patented endless flight vortex auger design and optional dual header drive enable high-capacity feeding of John Deere SPFH. Key advantages are the throughput boost in high-yielding crops but also the easy handling of uneven windrows.

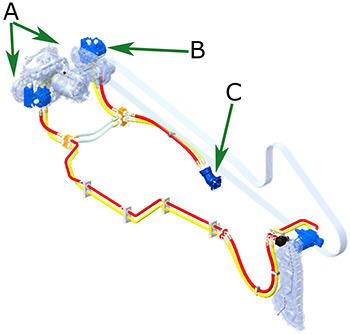

Power distribution gearbox (A), header pump (B), and header motor (C)

Power distribution gearbox (A), header pump (B), and header motor (C)John Deere SPFH come with variable header drive in base. The header speed is automatically synchronized with the feeding speed and length of chop through a hydrostatic IVT™ drive system. This ensures a gentle and even crop transfer from the header into the machine without blocking or disrupting material transition. Producers receive the benefit of high chopping quality and full leverage of the header and crop flow potential.

Dual header drive for the SPFH and the 6X9 Series Pickups complements the benefits of the variable header drive. While the variable header drive automatically synchronizes the pickup auger and harvester feeding speed, the dual header drive with its individual hydraulic drive of the pickup tines is speed matched with vehicle speed to ensure clean crop picking in changing conditions and windows.

Speed synchronization between the SPFH and header

Speed synchronization between the SPFH and headerTines speed up and slow down with forward speed while the pickup auger speed is still synchronized with the length of chop and feedroll speed. Producers benefit from a better quality of chop, smoother feeding, and an easy-to-utilize harvesting system.

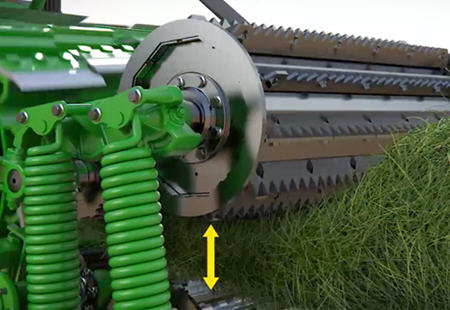

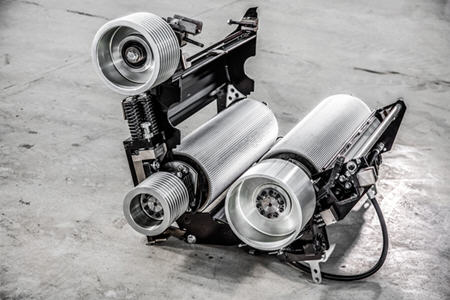

The 9000 Series SPFH offer the hydraulic feedroll dampener in base. Next to the four individual springs applying high pressure on the crop mat entering the machine, the dampener supports crop compaction in uneven crop conditions and ensures smooth feeding even at the highest feeding speeds when chopping for a very long period.

Hydraulic feedroll dampening

Hydraulic feedroll dampening Crop compaction and even feeding at the feedroll

Crop compaction and even feeding at the feedrollA state-of-the-art metal detector scans for metal in the crop mat and stops the intake in case of tripping. Optionally, this safety device can be completed with a unique stone detection feature that senses for knocks and abnormal feedroll movement. Two redundant sensors developed for this application improve solid foreign object detection and minimize false tripping caused by lumps or uneven windrows.

The John Deere 9000 Series Self-Propelled Forage Harvesters (SPFH) have been developed with a clear focus on machine performance: more throughput and less fuel consumption while providing maximum uptime and low cost of operation.

A key success factor is the concept of lower engine rpm at higher harvesting component speeds.

The top-model 9700, 9800, and 9900 SPFH are equipped with a Liebherr 12-cylinder V-engine with 24-L displacement. The Liebherr D9512 is a state-of-the-art engine and delivers what a high-performance forage harvester requires:

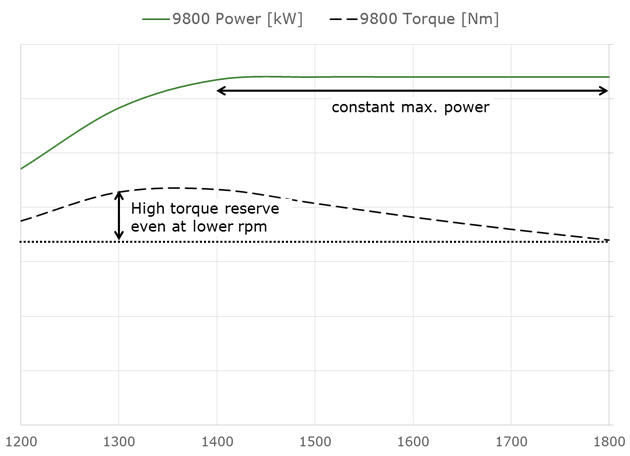

Torque and power of the Liebherr engine

Torque and power of the Liebherr engineThe broad maximum power range of the Liebherr V12 engine cuts off the less-efficient rpm area above 1800 rpm. The rising torque curve down to 1300 rpm enables efficient operation of the machine in the lower rpm range.

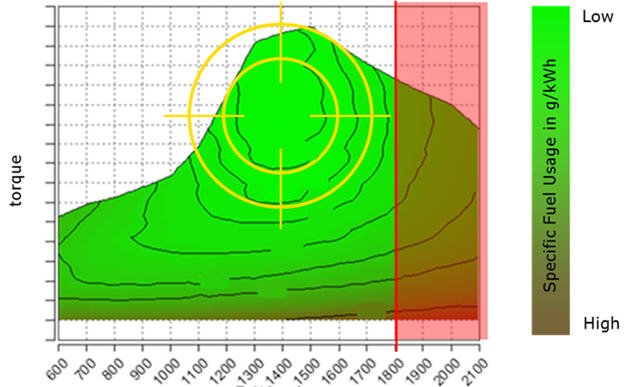

To reach maximum efficiency and performance, all machine component speeds are re-worked and laid out for best function in the 1400 to 1800 engine rpm range. This also leads to better fuel efficiency with an optimum range from 1250 to 1600 rpm, where the engine has its lowest specific fuel consumption (g/kWh).

Specific fuel usage in rpm range

Specific fuel usage in rpm rangeThis unique concept delivers undisputed customer value:

*Compared to replaced models

Liebherr is a trademark of Liebherr-International AG.

John Deere Premium KP™

John Deere Premium KP™ John Deere XStream KP™

John Deere XStream KP™All 9000 Series Self-Propelled Forage Harvesters (SPFH) can be operated with or without a kernel processing unit in position. When not in use, a crop transition chute swings into position at a few turns of a crank. The crop transition chute comes standard on all harvesters.

Also available on all SPFH is the optional dismounting crane for easy kernel processing swing outside the service compartment.

The 9000 Series SPFH feature the AutoLube central greasing harness; the respective central greasing equipment is available on the Premium Kernel Processor as well. The XStream Kernel Processor features an automatic pressurized oil lubrication.

For the 9000 Series, two types of kernel processors (KP) are offered: the John Deere Premium KP and the John Deere XStream KP. Both kernel processors have been tested and proven by independent experts during corn harvest in 2016 and 2017.

The 9600, 9700, and 9800 SPFH can be equipped with the John Deere XStream KP or the John Deere Premium KP. For the 9900, only the heavy-duty XStream KP solution is available.

On the 9000 Series, the proven John Deere Premium KP can be installed on the 9600, 9700, and 9800 models. With their highly intense processing, they deliver the best results at any length of cut.

The Premium KP has a standard KP housing with grease lubrication in base. The roll diameter is 240 mm (9.45 in.) with 32 percent speed differential. As an option, 40 percent speed differential can be installed, if required.

The following rolls are available for the Premium KP:

With Dura Line rolls, a longer lifetime and less wear can be reached, resulting in less cost of operation.

For an easy and uncomplicated mounting and dismounting of the Kernel Processor, a crane with electric winch can be installed as an option.

The John Deere XStream KP is made for high-horsepower machines and stands for extreme kernel processing at any length of cut.

The XStream KP rolls are manufactured and delivered by Scherer Inc., which is located in South Dakota, Unites States. The kernel processor fits all 9000 Series models (9600 through 9900). As Scherer Inc. has a strong focus on dairy forage production and is the leading company in KP roll designs and manufacturing since 1999, a strong statement is set in regards to kernel processing and forage quality.

More information about Scherer Inc. can be found on their website: https://www.schererinc.com/

The XStream KP is equipped with a heavy-duty housing with KP roll quick-exchange system and pressurized oil lubrication. The roll diameter is 250 mm (9.8 in.) with 50 percent speed differential. As an option, the XStream KP can be equipped with bearing temperature monitoring.

The following rolls are available for the XStream KP:

In comparison to the Dura Line sawtooth rolls, the Dura Line XCut rolls have a spiral groove sawtooth profile, delivering excellent processing, especially at long lengths of cut. The spiral groove design delivers highly processed plants and smashed kernels.

Due to a special heat treatment, the coating is extremely wear resistant and has an extraordinarily smooth surface. This results in a permanent fast chopping process while the fuel consumption remains low.

Tests show that while chopping in the same crop conditions and chopping the same tonnage, Dura Line parts last four times as long as, or longer than, standard parts. Time and money associated with replacing parts are significantly reduced.

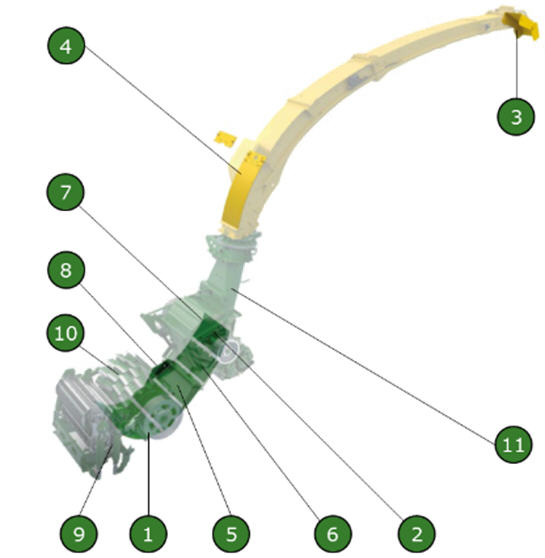

Dura Line parts cover nearly every wear part that does not already have a high-wear solution. The main crop flow elements are hardened and more resistant, even in the toughest conditions. Dura Line parts include spiral band, knife brackets, front chute, grass channel blower band, blower side liners, spout liners, and spout caps.

Three packages are available to match different producer requirements:

Producers have the ability to equip their 8000 or 9000 Series Self-Propelled Forage Harvesters (SPFH) with Dura Line components for extended part lifetime and lower cost of operation.

Three packages are available to match different producer requirements:

| # | Dura Line™ Component | Basic | Premium | Ultimate |

| 1 | Spiral band (cutterhead floor) | √ | √ | √ |

| 2 | Accelerator band | √ | √ | √ |

| 3 | Spout flap | √ | √ | √ |

| 4 | Spout wear liners | √ | √ | |

| 5 | Front chute base liner | √ | √ | |

| 6 | Grass chute base liner | √ | ||

| 7 | Accelerator side wall liners | √ | ||

| 8 | Front chute side liners | √ | ||

| 9 | Smooth roll scraper | √ | ||

| 10 | Dura Line knife holders | √ | ||

| 11 | Transition front liners (Model year 2019) | √ | ||

| 12 | Dura Line Plus Shearbar | √ |

Dura Line spout and wear parts

Dura Line spout and wear parts| Option code | Description |

| 2720 | Standard wear machine |

| 2721 | Dura Line Basic |

| 2722 | Dura Line Premium |

| 2723 | Dura Line Ultimate |

HarvestLab measures dry matter on the go

HarvestLab measures dry matter on the go Dry matter sensor mounts on the spout

Dry matter sensor mounts on the spoutThe HarvestLab sensor mounts to the top of the discharge spout and takes accurate dry matter and ingredient readings (more than 4000 measurements per second) of the crop through the sapphire glass lens as crop passes through the spout. This is the same technology forage labs use to measure dry matter. HarvestLab with John Deere Constituents Sensing measures dry matter, and has the ability to measure sugar, starch, acid detergent fiber (ADF), neutral detergent fiber (NDF), and crude protein in corn silage as well as ensiled material when used as a stationary unit.

When HarvestLab is used in conjunction with Harvest Monitor™, a wealth of important information becomes available to the operator, including productivity in acres per hour, throughput in tons per hour, total area harvested, total crop mass harvested, yields, and dry matter.

When the HarvestLab is used in conjunction with an 8000 or 9000 Series Self-Propelled Forage Harvester (SPFH) and a GreenStar™ display, AutoLoc™ functionality is automatically present. AutoLoc automatically varies the length of cut according to the desired crop-dry matter correlation settings based on the dry matter readings from the HarvestLab sensor.

| Crop | Material | Dry Matter | ADF* | NDF** | Starch | Protein | Sugar | Crude Fibre (XF) | Crude Ash (XA) |

| Corn silage | Freshly harvested and ensiled | Yes | Yes | Yes | Yes | Yes | No | No | No |

| Alfalfa | Yes | Yes | Yes | No | Yes | Yes | No | No | |

| Snaplage | Yes | Yes | Yes | Yes | No | Yes | No | No | |

| Whole crop silage | Yes | Yes | Yes | Yes | Yes | No | No | No | |

| Grass | Yes | Yes | Yes | No | Yes | Yes | Yes | Yes |

*ADF - Acid Detergent Fibre

**NDF - Neutral Density Fibre

| Key Specs | 9900-forage-harvester Current Model |

|---|---|

| Maximum power at 1800 rpm | 713 kW 970 PS / 956 hp |

| Engine | Type Liebherr Exhaust emission regulation compliancy: Final Tier 4 / Stage V Displacement 24.2 L 1476.8 cu in. Model D9512 A7 04 Cylinders V 12 |

| Fuel system | Common rail plus four valves |

| Fuel tank capacity | 1,500 L 396.3 U.S. gal. |

| DEF tank capacity ( for FT4 or EU Stage V emission level) | 103 L 23.8 U.S. gal. |

| Hand wash tank capacity | |

| Engine power | |

| Maximum power at 1800 rpm | 713 kW 970 PS / 956 hp |

| Maximum power at 1900 rpm | |

| Rated power at 2100 rpm | |

| Fuel tank capacity | 1500 L 396.3 U.S. gal. |

| DEF tank capacity ( for FT4 or EU Stage V emission level) | 103 L 23.8 U.S. gal. |

| Engine | |

| Manufacturer | |

| Type | Liebherr |

| Model | D9512 A7 04 |

| Displacement | 24.2 L 1476.8 cu in. |

| Cylinders | V 12 |

| Speed on road | |

| Engine/ground speed management | |

| Fuel system | Common rail plus four valves |

| Cooling system | |

| Cooling system capacity | 130 L 34.34 U.S. gal. |

| Cooling fan drive | Direct |

| Driveline | |

| Ground drive | Prodrive™, autoshift transmission, differential lock (automatic and manual), automatic wet brake system Engine rpm on road: 1200-1800 rpm |

| Hydraulics | Load sensing |

| Crop harvesting unit | Harvest channel wide |

| Crop flow components | Low-friction crop-flow concept |

| Main clutch | Dry clutch |

| Number of discs | Two discs |

| Main driveband | Reinforced with Kevlar inserts |

| Belt tensioning | Active, hydraulic pressure |

| Main driveband, polybelt belts | Nine ribs |

| Header drive | |

| Electrical system/Electrical and hydraulic system | |

| Type/voltage | 12 / 24 V |

| Batteries/battery quantity/capacity | 3 x 174 amp-hr |

| Alternator | 14 V - 200 amp 24 V - 140 amp |

| Hydraulic system capacity | 50 L 13.2 U.S. gal. |

| Ground drive | |

| Type | |

| Differential lock | Manual and automatic |

| Maximum transport speed | ProDrive transmission: 20 / 25 / 30 / 40 km/h 12.4 / 15.5 / 18.6 / 24.9 mph |

| Rear axle type | Hydro-mechanical 4WD |

| Automatic wet brake system | Standard |

| Engine rpm - Management | Standard |

| Cab | |

| Tilt and extend steering column | Standard |

| Air conditioning and heater | Standard - ClimaTrak |

| Cool box | Optional |

| Trainee seat | Standard |

| Hectare counter | Standard |

| Operator information system | Cornerpost display |

| CAN-BUS electronics | Standard |

| Operator's seat | Air-suspension seat optional |

| Side window wiper | Rear and side window wiper optional Parallel-type windscreen wiper |

| Electric adjust and heated | Optional on rear view mirrors |

| Rear view mirrors | Standard |

| Hand wash tank capacity | |

| Machine management solutions | |

| Yield monitoring | Harvest Monitor™ optional |

| Documentation | Harvest Doc™ optional |

| Crop analysis | HarvestLab™ optional |

| Length-of-cut control based on crop parameter | Infinitely variable length-of-cut (IVLOC™) standard AutoLOC optional - use with HarvestLab |

| Satellite (GPS) assisted steering | AutoTrac™ optional |

| Crop-harvesting units | |

| Header height control | Advanced header control (AHC) optional |

| Grass pick-ups (transport width) | 3.0, 4.0, 4.5 m 9.8, 13.1, 14.8 ft |

| Maize or corn headers | |

| Driveline | |

| Header connection | |

| Harvest channel | |

| Length of cut | |

| Feeding system/Feedrolls | |

| Feed roll frame opening | Swing away, 37-45 degree (angle) |

| Number | Four |

| Metal detector | Standard Stone detector is optional |

| Width, front | 830 mm 32.7 in. |

| Standard feed roll drive | Hydro feedroll drive IVLOC standard Infinitely variable header drive speed standard |

| Optional feed roll drive | |

| Cutterhead | |

| Type | Dura-Drum™ cutterhead |

| Cutterhead housing width | |

| Knife drum width | 850 mm 33.5 in. |

| Knife drum diameter | 670 mm 26.4 in. |

| Speed at rated engine speed | Standard - 1170 rpm Optional - 1350 rpm |

| Knife types available (crop) | Straight - grass Curved - corn |

| Number of knives | |

| Shear bar, reversible | |

| Shear bar adjust | |

| Knife sharpening system | |

| Reverse rotation | Yes |

| Automatic from cab | Yes, remote from cab |

| Reverse drive | Standard |

| Reverse speed | |

| Sharpening modes | |

| Kernel processor | |

| Type | John Deere Premium KP, John Deere XStream KP |

| Quick-change | Quick kernel processor - swing in/swing out |

| Quick KP removal | Optional crane with remote-controlled electric hoist |

| John Deere Premium KP | |

| Housing | |

| Lubrication | |

| Roll diameter | |

| Speed differential / Roll speed (lower) | |

| Maize, roll teeth number (speed differential) | |

| Wholecrop, roll teeth number (speed differential) | |

| Sorghum, roll teeth number (speed differential) | |

| Weight | |

| Available KP rolls | |

| John Deere XStream KP | |

| Housing | |

| Lubrication | |

| Roll diameter | 250 mm 9.8 in. |

| Speed differential / Roll speed (lower) | |

| Bearing temperature monitoring system | |

| Maize, roll teeth number (speed differential) | 110/145 (50 percent) |

| Wholecrop, roll teeth number (speed differential) | 145/165 (50 percent) |

| Sorghum, roll teeth number (speed differential) | 238 (32 percent) |

| Weight | |

| Available KP rolls | |

| Serrated roller (kernel processor) | |

| Maize, roll teeth number (speed differential) | |

| Wholecrop, roll teeth number (speed differential) | |

| Sorghum, roll teeth number (speed differential) | |

| Weight | |

| Disk type (kernel processor) | |

| Number of disks (top/bottom) | |

| Diameter of disks | |

| Weight | |

| Blower/Crop accelerator | |

| Rotor diameter/housing width | 560 / 620 mm 22.86 / 24.41 in. |

| Number of blades | 10 |

| Speed (option) | 1890 rpm |

| Spout | |

| Rotation, degrees | 210 degree (angle) |

| Hydraulic height position | Hydraulic raise and lower standard Automatic spout positioning optional |

| Double-cap deflection | Standard |

| Number of wear liners | |

| Reach from center line (Optional) | 6 or 8 row: 4.73 m 15.5 ft 10 row: 5.87 m 19.3 ft 12 row: 6.71 m 22 ft |

| Maintenance | |

| Rotary radiator screen cleaner | Standard |

| Automatic lubrication system | AutoLube optional |

| Engine oil and filter change duration | 1000 hours |

| Vehicle | |

| With front tires | 710/70R42 |

| With rear tires | 620/60R30 |

| Transport length (without header) | 6.6 m 21.7 ft |

| Transport width (without header) | 3.1-3.7 m 10.2-12.1 ft |

| Transport height (to cab roof) | 3.89 m 12.75 ft |

| Working height (maximum) | Height to spout: 6.60 m 21.65 ft |

| Approximate weight (without header) | |

| Propelling drive | |

| Transmission | |